Aluminum profile is used for a variety of purposes. For example, a strip of metal is used as a decorative finish, when assembling furniture for medical facilities, as well as in the manufacture of trading counters, display cases and balconies. Also used to create canopies and bicycles. For example, a children's bicycle 20 "was made from aluminum. Women's bicycles are equipped with an aluminum frame. They are characterized by a high degree of strength and lightness. To extend the life of the profile, polymer paint is applied to it.

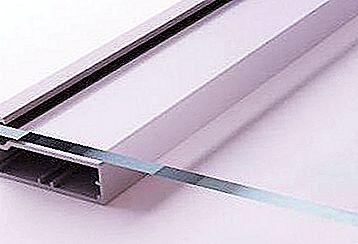

Glazing of balconies and loggias with aluminum profile

The aluminum frame for glazing balconies and loggias makes it possible to build a practical and comfortable lounge, study or workshop from the auxiliary room. Additional living space is of assistance to small apartments.

Balconies, glazed with aluminum profiles, are resistant to adverse weather factors, as they have an anti-corrosion property. Metal structures have unlimited possibilities and various configurations. The aluminum profile for the balcony can have a sliding modification. The casement windows in this case are suspended on casters and securely fixed in the rails located above and below.

Aluminum structures can include from 2 to 8 flaps that can be locked with snap locks. From the street side, such devices cannot be opened.

In order for the balcony aluminum frame to retain heat well, aluminum profiles with special heat-insulating inserts are used. Such windows will provide reliable protection against wind, hail and rain and create comfort.

Varieties of aluminum glazing

Aluminum balcony frame can be of two types: cold or warm. If you pursue the goal of protecting the loggia as much as possible from precipitation, then in this case a cold view is suitable. Warm glazing creates more comfortable conditions on the loggia and balcony.

Cold glazing prevents the penetration of wind, rain or snow, but cannot serve as protection against low air temperatures. In the warmer months, linen can be dried on the balcony, glazed by the cold method.

Warm glazing allows you to use a balcony or loggia year-round. For glazing, a profile with a heat-insulating property is used. Thermal inserts of complex configuration reduce the level of thermal conductivity of the aluminum profile, which contributes to the heating of the room.

The advantages of glazing balconies or loggias with an aluminum profile

The main advantages of this process include:

- Lightweight construction, which makes the wizard easier and ensures its quick installation. Lightweight configurations can withstand even some types of metal railings.

- Resistance to fire.

- No noise movement.

- Closing and opening the wings by sliding, which is ensured by means of special sleds. This design has gained particular popularity.

- High level of comfort during use and safety.

- Saves usable space.

- A wide range of color schemes.

- Resistance to rust and durability.

- The possibility of glazing the balcony beyond the parapet. This option is suitable for small balconies.

Cons aluminum profile

The aluminum profile frame has several disadvantages:

- Low sound insulation due to insufficient sealing. As the temperature changes, aluminum is compressed and expanded. Such vibrations can provoke deformation of the profile at the points of contact with the wall.

- Locks locks freeze in the winter, making it extremely difficult to open the wings.

Installation of aluminum sliding windows

Aluminum sliding windows are mounted in the same way as other windows made of wood or plastic. When installing the structure, it is necessary to check the integrity of all components, to identify defects, chips and other types of damage.

Installation steps

Installing an aluminum frame involves the following steps:

- Installation of guides that move the sash. The dimensions of the length and height of the sides of the structure are taken. The profile is cut in size, then the fitting operation is performed.

- The guides are fastened to the frame by means of screws.

- The insulating glass is inserted. In the lower part are mounted rollers for sliding.

- The sealing material is fastened to the sashes of the frame.

- Sashes are mounted in rails located above and below.

- The valves are regulated by tightening the screws in the lower part of the profile.

Basic installation steps

- The window frame is being installed in the window opening. It is fastened with wedges.

- The aluminum frame is aligned using a measuring tool.

- The frame drills the holes needed for fasteners.

- According to the marks made in the wall, holes are drilled to secure the frame.

- Anchor plates are inserted, fastened with dowels to the wall. The frame is mounted.

Giving the window the necessary tightness

To seal the window mounted ebb and window sill. To this end, the following operations are carried out:

- the perimeter of the outer part of the frame is glued with a special tape;

- the tide is screwed to the bottom of the frame;

- the gaps between the frame and the ebb are closed by foam for installation;

- after hardening of the foam, its excess is removed;

- the window sill is mounted in a groove located in the lower part of the frame;

- windows are regulated by the level of the windowsill;

- all cracks are processed with construction foam;

- with the help of a sealant, the voids between the windowsill and the frame are filled.

The final stage of window installation is the installation of a double-glazed window, hanging the sashes and adjusting the fittings. To install the package requires the participation of two masters.

All the flaws in the adjustment are eliminated by means of a special hexagon.

The tool is inserted into the screws for adjustment. This is the fit of the frames, which should fit snugly.

The use of aluminum frames in the manufacture of bicycles

Many are interested in whether a steel or aluminum bike frame is better. A few years ago, it was the steel frame that was very popular. Throughout the period of production of bicycles, the technology for manufacturing steel structures has been improved to the limit.

In recent decades, when creating bicycles, such types of steel are used, in which chromium and molybdenum are included as alloying components. Such frames are called "chromomolybdenum". Sometimes cheaper steel grades are used.

The advantages of steel frames

An important advantage of such a frame is its high level of suitability for repair. In the event of a malfunction, the structure can be restored using conventional welding. Another positive feature of the design is that it can absorb the bike on rough roads, damping vibration and shock.

Cons of steel frames

The disadvantages of steel frames include heavy weight and susceptibility to rust. Newer devices are always coated with enamel, which serves as protection against corrosion. But during use, such a coating may be damaged. Therefore, it is recommended that such a frame be checked and painted over the damaged areas with paintwork once a year. To protect against rusting the internal cavity made of steel, it is recommended that the frame of the new bicycle be treated with a coating against corrosion.

Features of aluminum frames

In recent years, an aluminum frame bike has become increasingly popular. The alloys used for the manufacture of bicycles are indicated by a four-digit number (for example, 6061 or 7005). It is believed that a higher number is an indicator of better quality. In fact, the number is just an indicator of the composition of the alloy. So, in aluminum under number 6061 magnesium, silicon and copper are included. And zinc is added to the 7005 series.

The main advantage of the aluminum frame in comparison with the steel counterpart is its light weight. Aluminum frames are made thicker to achieve the level of strength of steel, while they are still lightweight.

The aluminum frame rusts less, but when driving through the city streets in winter, treated with salt and various reagents, rust can cause deformation and damage to the frame. If the bike is used in winter, it should be washed more often.

A few years ago it was widely believed that an aluminum frame is less reliable than a steel counterpart. But the production technology is in constant development, and now the companies give the same guarantee on an aluminum frame as on a steel frame. Any mechanism is susceptible to serious damage, but the aluminum frame can break only in a serious accident. The same applies to a steel product.

The disadvantages of aluminum frames include a higher cost and limited maintainability. Fixing an aluminum alloy is complex. To repair such a frame, argon welding is required.

An important characteristic of this design is its high level of rigidity, due to which the bike is very easy to handle. But at the same time, aluminum is not able to mitigate irregularities, so such bikes are equipped with additional shock absorbing devices. A female bike with an aluminum frame is considered the most optimal model, as it is easy to manage.