Often you need to familiarize yourself with the question of how to check the transformer in advance. After all, when it fails or unstable operation, it will be difficult to look for the cause of the equipment failure. This simple electrical device can be diagnosed with a conventional multimeter. Consider how to do this.

What is the equipment?

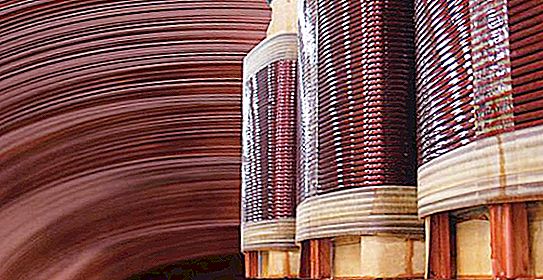

How to check the transformer if we do not know its design? Consider the principle of operation and varieties of simple equipment. Coils of a copper wire of a certain cross section are applied to the magnetic core so that conclusions remain for the supply winding and the secondary one.

Energy is transferred to the secondary winding in a non-contact manner. Then it becomes almost clear how to check the transformer. Similarly, the usual inductance is called an ohmmeter. The turns form a resistance that can be measured. However, this method is applicable when a given value is known. After all, the resistance can change up or down as a result of heating. This is called inter-turn closure.

Such a device will no longer produce a reference voltage and current. An ohmmeter will show only an open circuit or a complete short circuit. For additional diagnostics, a short circuit to the case is used with the same ohmmeter. How to check the transformer without knowing the winding leads?

This is determined by the thickness of the outgoing wires. If the transformer is step-down, then the output conductors will be thicker than the supply ones. And accordingly, on the contrary: the raising lead wires are thicker. If two windings are output, then the thickness may be the same, this should be remembered. The surest way to look at the markings and find the technical specifications of the equipment.

Kinds

Transformers are divided into the following groups:

- Lowering and increasing.

- Power often serve to reduce the supply voltage.

- Current transformers for supplying a consumer with a constant current value and holding it in a given range.

- Single and multiphase.

- Welding destination.

- Impulse.

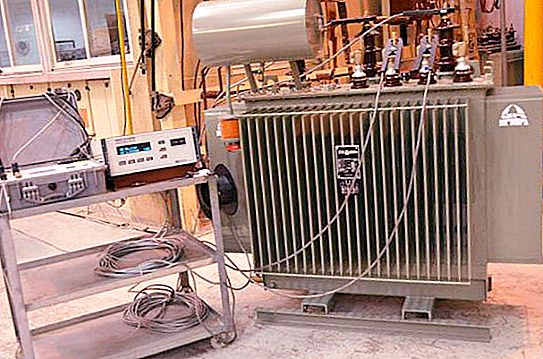

Depending on the purpose of the equipment, the principle of the approach to the question of how to check the transformer windings changes. With a multimeter, you can ring only small-sized devices. Power machines already require a different approach to troubleshooting.

Call method

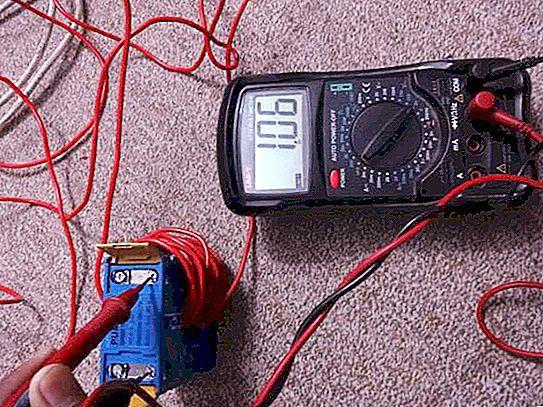

The diagnostic method with an ohmmeter will help with the question of how to check the power transformer. They begin to ring the resistance between the terminals of one winding. So establish the integrity of the conductor. Before this, they inspect the housing for the absence of deposits, inflows as a result of heating of the equipment.

Next, measure the current values in Ohms and compare them with the passport. If none are available, then additional live diagnostics will be required. It is recommended that you ring each terminal with respect to the metal case of the device where the ground is connected.

Before taking measurements, disconnect all ends of the transformer. It is recommended to disconnect them from the circuit for their own safety. They also check the presence of an electronic circuit, which is often present in modern power models. It should also be removed before testing.

Infinite resistance speaks of whole isolation. Values of several kilograms already raise suspicion of a breakdown on the case. It can also be due to accumulated dirt, dust or moisture in the air gaps of the device.

Energized

Tests with supplied power are carried out when the question is how to check the transformer for inter-turn short circuit. If we know the value of the supply voltage of the device for which the transformer is intended, then the idle value is measured with a voltmeter. That is, the lead wires are in the air.

If the voltage value differs from the nominal, then conclusions are drawn about the inter-turn short circuit in the windings. If cracking, sparking is heard during the operation of the device, then it is better to turn off such a transformer immediately. He is defective. There are tolerances for measurements:

- For voltage values may vary by 20%.

- For resistance, the norm is a spread of values of 50% of the passport.

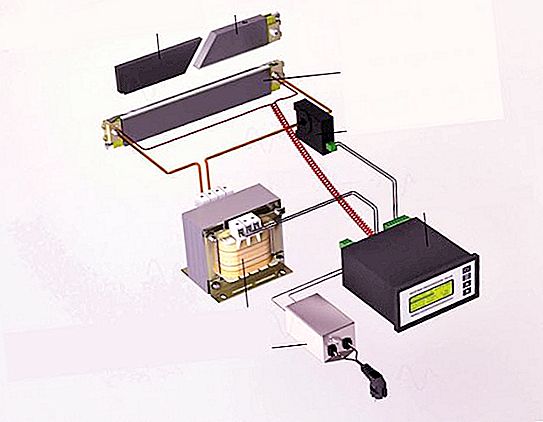

Ammeter measurement

We will figure out how to check the current transformer. It is included in the chain: full-time or actually made. It is important that the current value is not less than the rated value. Measurements with an ammeter are carried out in the primary circuit and in the secondary.

The current in the primary circuit is compared with secondary readings. More precisely, they divide the first values into those measured in the secondary winding. The transformation coefficient should be taken from the directory and compared with the obtained calculations. The results should be the same.

The current transformer must not be measured at idle. In this case, too high a voltage can be formed on the secondary winding, which can damage the insulation. It is also necessary to observe the polarity of the connection, which will affect the operation of the entire connected circuit.

Typical malfunctions

Before checking the microwave transformer, we give frequent varieties of breakdowns that can be fixed without a multimeter. Often, power devices fail due to a short circuit. It is installed by inspecting circuit boards, connectors, connections. Less commonly, mechanical damage to the transformer housing and its core occurs.

The mechanical wear of the transformer terminal connections occurs on moving machines. Large supply windings require constant cooling. In its absence, overheating and melting of the insulation is possible.

TDKS

Let's figure out how to check a pulse transformer. An ohmmeter can only establish the integrity of the windings. The operability of the device is set when connected to a circuit where a capacitor, load, and sound generator are involved.

A pulse signal in the range from 20 to 100 kHz is launched onto the primary winding. On the secondary side, measurements are made by an oscilloscope. Establish the presence of pulse distortion. If they are absent, draw conclusions about a working device.

Distortion of the oscillograms indicates spoiled windings. Repairing such devices is not recommended on their own. They are set up in the laboratory. There are other schemes for checking pulse transformers, where they investigate the presence of resonance on the windings. Its absence indicates a malfunctioning device.

You can also compare the shape of the pulses applied to the primary winding and coming from the secondary. Deviation in shape also indicates a transformer malfunction.

Multiple windings

For resistance measurements, the ends are freed from electrical connections. Choose any output and measure all resistances relative to the others. It is recommended that you record values and mark verified ends.

So we can determine the type of connection of the windings: with medium leads, without them, with a common connection point. More common with a separate winding connection. Measurement can be done with only one of all the wires.

If there is a common point, then the resistance is measured between all available conductors. Two windings with an average output will matter only between the three wires. Several conclusions are found in transformers designed to work in several networks with a nominal value of 110 or 220 volts.