The clamping screw for formwork is one of the most important elements in the construction of the facility, which contributes to the optimal exposure to the design indicators of the future construction. In this case, compliance with the exact parameters and dimensions according to the project plays a significant role. Since the design in question is prefabricated, its implementation depends on the correct use of materials and the features of the components used, as well as the fasteners.

general information

The clamping screw for formwork is a part that takes up the main load created by the pressure obtained from the load after being placed in the concrete mortar. For these reasons, increased requirements apply to such designs.

The general indicator of the formwork configuration depends on the strength of the middle and extreme elements. This part fastens the parts of the module, fixing them in the desired position. The formwork coupling screw and plastic universal coupler must meet certain specifications. Let's consider these features further.

Clamping screw for formwork

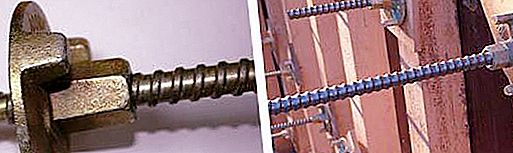

The part in question is also called a tie bolt or stud. The element serves to fix the formwork panels at the required distance between each other. In this context, the length of the screw determines the thickness of the cast structure. After fixing the shields, they gain stability and do not deform under the load from pouring concrete mortar.

In Yekaterinburg, the clamping screw for formwork must meet a number of mandatory requirements:

- Screw threads should exclude the possibility of spontaneous movement.

- The bolt is designed for increased tear resistance.

- The material for manufacturing the structure must be resistant to corrosion processes, equipped with a protective coating.

- To facilitate the subsequent dismantling of the formwork, the coupling screw is equipped with a protective tube made of polymers.

Standard kit

The clamping screw for formwork includes a special stud with an external thread diameter of 17 mm. The length of the element is selected depending on the thickness of the molded formwork according to the project. As a rule, this indicator is from 0.5 to 3 meters.

Also included is a pair of galvanized nuts, the basis for which is cast iron. Reliable fixation and tight fit provides a wide flat platform in place of pressing the nut. The part is mounted on the outside of the shield, does not interact with the concrete mortar. To increase the bearing area, the washer supplied with the nut is used.

In order to correctly select the coupling bolt along the length, it is necessary to take into account the thickness of the cast structure and the similar indicator of the formwork panels. The calculation is carried out according to the following scheme: the thickness of the proposed formwork and the doubled similar indicator of the boards (if two elements are used) are added. 300 mm are added to the result (margin for tightening the nuts).

Plastic analog

You can buy a clamping screw for plastic formwork in Moscow. The item is a pair of rods made of reinforced and elastic plastic (polycarbonate), used to fix removable or non-removable formwork with a parallel arrangement of boards. A thread for mounting the mounting washers is provided on the outside of the fixture.

With each other, the rods are joined by means of an effective lock called "groove-spike". Such a configuration makes it possible to adjust the length of the screed according to the necessary parameters, the part is installed in special forms with a pitch of 50 mm. If the rods are insufficient in length, they can be increased by installing special extension cords.

Features

The clamping element has a cross-sectional configuration that provides successful resistance to compression loads. This feature allows you to avoid displacement of the walls inward. The provided special triangular protrusions on a coupler give the chance to fasten reinforcing bars. The device is very convenient to install, special tools are not required for installation, a small mass facilitates the transportation of a large number of studs manually, without being distracted once again from work.

Technical specifications

The clamping screw for formwork in Lipetsk is available to order online. To make it easier to determine the type of fixtures, study the technical indicators of plastic systems for screeds:

- It is possible to use with various forms of formwork from virtually any material.

- The extension cord allows you to adjust the thickness of the workpiece from 300 to 600 mm.

- The system is characterized by high tensile strength, and withstands the pressure of concrete mortar.

Installation work

The main processes in monolithic construction consist of the following stages:

- The formwork is installed, which serves to indicate the configuration of future wall ceilings.

- A reinforcing cage is made between the walls.

- Concrete mixture is being poured.

- After hardening, the formwork panels are dismantled, if a fixed-type design was used, they remain intact.

Formwork installation:

- Holes with a diameter of 22 mm are drilled in shields.

- The hairpin is inserted on one side, a clamp is put on it, a polymer pipe segment, and a second clamp. The tops of the stops should face away from the panels.

- The tightening screw is discharged through the socket in the parallel shield.

- Mount washers of flat type on both sides, nuts are screwed on with simultaneous installation of caps.

- To fix a pair of parallel walls without skewing, at least three tie rods must be used.