Shipbuilding is one of the most difficult areas of human activity. There are many different concepts in this field, the meaning of which is known only to professionals. One of these terms is "stem". This word can also be found in scientific and fiction when describing ships.

The meaning of the term

The stem is the front, most robust design in the bow of the ship. It is represented by a steel beam, as well as a forged or cast strip curved in the shape of the bow of the vessel.

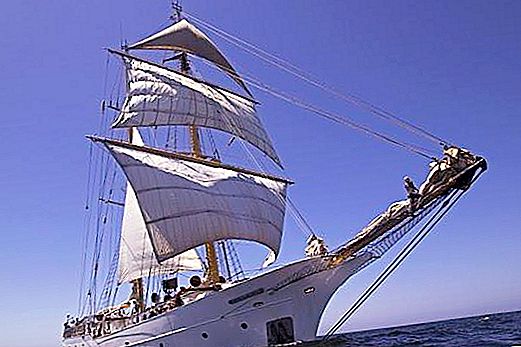

Depending on the conditions in which the vessel is operated, what speed and quality it has, the hull is given the appropriate shape. The stem is a kind of continuation of the keel of the ship. The transition to the keel line can be round, smooth or with a kink. The shape of the stem gives a general impression of the ship itself. Even visually, a ship can be considered high-speed if it has a forward stem projecting forward. A photo of this part of the ship is presented in the article.

Functions

The stem is the part that was used as a ram against smaller ships in older types of warships. Submarines or destroyers could also perform a similar task. A ship equipped with heavy stem is capable of breaking through the outer skin without serious damage to itself: a hole is formed above the waterline.

Modern ships are equipped with stakes capable of ramming even submarines, the manufacture of which uses very thick steel sheets. Since the bow of the ship’s hull is heavily impacted by wave impacts, the stomp of non-combat ships must also have a very solid construction.

What are the stems?

When choosing this or that stem, the purpose of the ship and its shape are taken into account. The following types are used in shipbuilding:

Leaning forward. In the underwater part, the stem turns at an angle into the keel of the ship, which gives the impression of forward striving. Due to such a stem, the lifting ability of the vessel to the wave improves.

- Clipper. It is similar in shape to a tilted stem. It is used in sailing ships.

- The bulb-like boat stem in the surface is represented by an inclined or concave line. The line under water has a teardrop shape. They are equipped with ships having a large hull width. Through the use of such a stem, it is possible to achieve a decrease in wave resistance and an increase in speed. Since during the keel qualities such a stem is highly susceptible to hydrodynamic effects, it is strengthened with the help of longitudinal and transverse stiffeners.

- Icebreaker. They have such an ice class ship stem. The line of this stem in the above-water part is slightly inclined forward. Closer to the surface of the water, the slope is 30 degrees. The same angle is maintained in the underwater until the transition to the keel line. Ships equipped with such stakes can easily sail on ice, pushing it with their weight.

Straight. Under water has a straight line, which smoothly turns into a keel. This stem has river vessels with free space on the deck, which float on a calm water surface. Straight stem is convenient for viewing the space in front of the bow of the ship in places with narrowings and when approaching the berths.

Execution options

These parts of the ships differ from each other also in design. In shipbuilding, the following types are used:

- Squared. This design is considered the oldest. Today, tugboats and small fishing vessels with a squared keel are equipped with such shafts. The pins in the ice class ships are equipped with special recesses (dowels) into which the outer skin sheets are inserted. This design allows the vessel to maintain tightness in case of damage.

- Cast. Unlike squared stem, its molded cross-sectional shape is easily fitted with a waterline. Due to the smooth connection of the sheets in front of the stem, the formation of water outlets is reduced. In order to increase the strength of cast rods in shipbuilding, longitudinal and transverse stiffeners are used.

- Sheet, or welded. These stems are intended for large, fully welded ships with a bow-shaped bow. In order to prevent deformation in the sheet stems, horizontal spacer sheets are used, which are known in the shipbuilding industry as nose breech bars. With their help, the connecting joints between the shafts and the sheets of the outer skin of the vessel overlap. A ship equipped with ice reinforcement has a longitudinal stiffener for sheet stub.