Work with glass in domestic conditions is not as common as in the case of wood or metal. The material is very capricious in processing, requires accuracy and accuracy, so inexperienced owners try to entrust such operations to specialists. Nevertheless, with proper dexterity, it is possible to perform high-quality cutting of glass without outside help. Oil glass cutter, which is considered the most durable and effective tool of this type, will help in this matter.

Features of oil glass cutters

As the name implies, such models differ in that the operating mechanisms are lubricated with oil. The rest of the tool resembles a traditional roller glass cutter. Actually, due to the presence of automatic lubrication, this option is more beneficial from the point of view of long-term or intensive use. The fact is that a glass-cutter roller oil in the process does not imply strong friction of the working head, which increases the service life. Conventional roller models, on the other hand, are spared the lubrication system and are therefore less durable. However, those who rarely deal with glass processing may well turn to standard versions without lubrication. There are also diamond glass cutters. They do not require the use of oil, but at the same time they have a high operational life. True, oil analogues are cheaper.

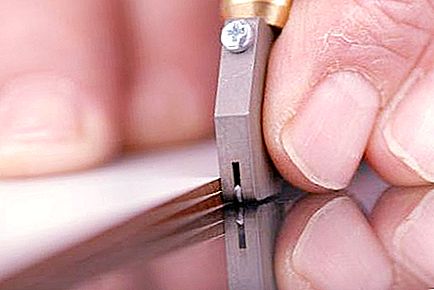

Device and principle of operation

Externally, the tool resembles a large handle with a small tank, at the end of which a working head with a spring mechanism is fixed. Oil is in the container. As for the cutting head, it is designed with the expectation of an automatic supply of lubricant during the movement of the roller. The function of this system minimizes the friction of parts, which increases the working life. But there is another task for the lubricant, which, incidentally, is devoid of diamond tools. When cutting, oil glass cutter collects small particles of brittle material due to a viscous lubricant. This nuance is important not only from a security point of view. Instant collection of glass dust facilitates the mechanical impact of the roller on the surface. Partly for this reason, an oil tool more easily copes with thick glass.

How to use oil glass cutter?

The workflow involves several steps. If you plan to cut ordinary glass up to 5 mm thick, then three steps will suffice. To begin with, a risk is formed that marks the line for further cutting. Then you can proceed to the crucial part - direct cutting. At this point, the workpiece should be installed on a resistant surface with a non-slip coating. Next, you must carefully and with little pressure draw the roller along the intended line. The final stage will be the breaking of the glass along the formed cut. Now you can turn to the question of how to cut materials with a thickness of more than 5 mm with an oil glass cutter. There are two main differences in working with such glass. First, risk and direct cutting is performed from two sides. Secondly, if in the case of thin glass the break can be done with hands protected by gloves, then in other cases, the use of pliers or wire cutters may be required. It is important to note that the tool must also be provided with a protective cloth that will prevent damage to the glass.

How to choose glass cutting oil?

There are not so many requirements for oil, but the duration of the tool depends on their compliance. First of all, the mixture should have a consistency sufficient for free passage into the feed channel. Otherwise, automatic lubrication simply will not work. The second condition is reduced to optimal adhesion - a sufficient viscosity coefficient of the composition will uniformly lubricate the oil glass cutter. The tool manual recommends that, as the best option, use a mixture of machine oil with kerosene, diluted in equal proportions. In practice, high-quality compositions stably flow from the reservoir to the working head and remain on it. During the cutting process, the oil may leave a streak of trace, but it should not flow abundantly from the glass cutter.

Silberschnitt Glass Cutter Reviews

The products of this brand will suit professionals who specialize in working with glass. Users note the good performance characteristics of the models of this brand. To create a quality cut, minimal effort is enough, after which the split is carried out evenly and without much pressure. However, there are also negative impressions of working with such a tool. So, in some versions, the Silberschnitt oil cutter is equipped with a blunt head, which makes it difficult to cut. In addition, many talk about the difficulties in working around the edge. Glass breaks or does not break at all without additional force. The rest of the models are very attractive both in terms of working qualities and appearance - a strict and concise design is a hallmark of the Silberschnitt tool.

Toyo Model Reviews

Inexpensive, but high-quality models that are suitable for use at home. As users note, some versions of this line have one caveat. Glass cutters with oil work inefficiently, and without it they can easily cope even with thick glass. In terms of ergonomics, there are no complaints. Simple design makes the device easy to use. There are operational features that this oil glass cutter has. Reviews emphasize that it is better to dip the head in oil - this will increase ease of use and increase the quality of the cut. In terms of reliability, the Toyo model is difficult to compare with professional modifications, but the combination of high-impact plastic and a damage-resistant head gives every reason to rely on the durability of the tool.

Reviews about glass cutters "Bison"

This is one of the best manufacturers of building tools in Russia, however, against the background of foreign brands, companies do not always manage to show a high level of quality of their products. Owners of oil glass cutters of this brand note the simplicity of the design, the ease of the tool and the rather average performance. The disadvantages of cutting are compensated by a low price, but for regular use, the Zubr oil glass cutter is hardly suitable. Even despite the stable operation of the lubrication mechanism, the working head is doubtful for many. Experienced craftsmen do not recommend performing critical operations with ceramics or thick glass with such a tool. But, for simple everyday tasks, if you have the proper skills with a domestic glass cutter, you can get good results. Again, the cost is about 100 rubles. It is consistent with the characteristics of this product.