At the word “mine, ” the imagination immediately draws an explosive device buried in the ground. First appeared in French, this word was originally associated with the earth and meant “mine”, “undermining”, which was often used during the siege wars. The fortified and defended cities in the course of hostilities were attacked with trenches and approaches undermined to their walls with the further laying of explosive charges filled with gunpowder in them. First, a mine was called an underground horizontal mine near the walls of the enemy, later the explosive device itself was called by this word. Also in French, the word “sapper” appeared. They called him a man who undermined and undermined enemy fortifications.

History

The use of explosive mechanisms stuffed with striking elements in many wars has proven the absolute effectiveness of their use to eliminate fortified structures, enemy infantry and their military equipment. Discoveries in the field of chemistry: the appearance of xyloidine, pyroxylin, liquid nitroglycerin, trotyl and nitrate - as well as the rich experience of warfare that mankind already had, served as a good impetus for the improvement of explosive devices.

Primitive bookmarks under enemy walls using bickford cords are a thing of the past. Their place was taken by modern products using special capsules - detonators and electric ignition systems.

Explosive mechanisms buried in the ground because of their secrecy have always been considered very dangerous. But time has shown that their effectiveness is not 100%, since the mine directly eliminated only the object that came into contact with it and left the others intact. A much better result could be achieved if the mine was above the ground. But in that case she would be visible. This shortcoming in the mine business demanded an immediate solution, which was the device, called the OZM-72. Let's consider it in more detail.

Mine OZM-72: TTX (performance characteristics)

The device by type belongs to anti-personnel fragmentation, explosive mechanisms jumping out with a circular defeat.

Steel is used to make the mine shell.

The total mass is 5 kg, of which 660 g is explosive.

Diameter - 10.8 cm, body height - 17.2 cm.

The OZM-72 mine is designed for weight from 1 to 17 kg, the temperature range of use is from –60 to +60 degrees, the radius of destruction does not exceed 30 m. The term of combat operation is unlimited. The mine is not equipped with self-liquidators and does not contain elements that do not allow it to be removed or rendered harmless.

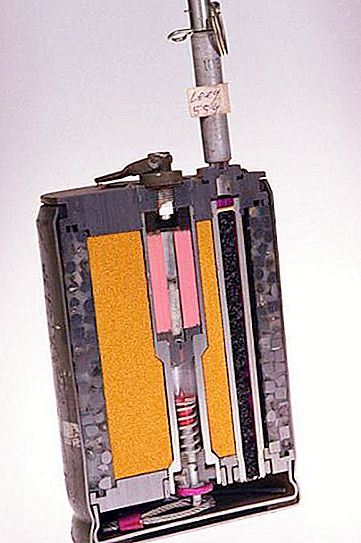

MUV and MVE-72 fuses

As a fuse can be a mechanical MUV or electromechanical MVE-72. Mechanical is very sensitive, which makes the process of clearing mines with it very dangerous.

Design features

Elements of OZM-72 are:

- Guide glass. Steel is used for its manufacture. At the bottom of the glass there is a special chamber designed to fasten the tension cable in it, connecting the glass to the percussion mechanism. The glass contains a housing with an explosive charge and fragments.

- Charge. As a charge for the OZM-72 mine, TNT is used, which fills the inner cavity of the holder. Located in the upper part of the central sleeve.

- Kick charge. Designed to push an explosive device out of the ground to a height of 1 m. For the manufacture of a knockout charge, smoke powder collected in a fabric bag is used. The charge is contained in a special tube.

- Shock mechanism. Placed at the bottom of the center sleeve.

- Detonating capsule. It is located in the slot of an additional detonator and is mounted only at the moment when the OZM-72 mine is directly installed.

- Carabiners and cables. Designed for fastening the checks of the explosive mechanism with wire extensions.

- Stretch marks made of wire. When installed in coils during installation, they reach a length of up to 15 m. They are intended for the arrangement of trap-extensions.

- Pegs made of wood and metal. Wooden stakes are used to equip stretch marks, and metal stakes are used for mounting mines in frozen ground and mounting a cable with carbines. For the production of metal stakes, a duralumin corner is used.

Destination

The OZM-72 explosive device is designed to completely eliminate or temporarily disable enemy infantry. The degree of damage from fragmentation elements, which are metal balls, can be different: from eliminating one soldier to several. This became possible due to the fact that the OZM-72 anti-personnel mines are hidden in the ground and are not visible from the side. And the knock-out charge available in their mechanism throws up a device that explodes already above the ground at a height of 1 m with a circular defeat of up to 30 m.

How does the OZM-72 mine work?

The principle of the mine’s operation is to throw a tearing steel shell, consisting of metal, cylindrical pieces, capable of scattering in a radius of up to 30 meters with a knockout charge from the guide cup to a meter high. The mine fires when it contacts a peg attached with a wire tie connected to a fuse pin.

It can be MVE-72. In this case, it is enough to touch the electrical wire connected to the check. Also used as a fuse MUV, which uses not electricity, but mechanics. To fire a mine, the enemy should hook a stretched wire - a banner connected at one end with a fuse. Subsequent detonation produces an ejection above the ground from a glass of charge, which is represented by a steel shell having TNT filling. During the interaction of explosives, the shell forms round and cylindrical damaging elements that scatter in all directions.

Bookmark Stages

How is the OZM-72 laid? The installation of the explosive mechanism is done manually in the ground or in the snow.

The bookmarking process consists of the following steps:

- arrangement of a hole with a diameter of up to 200 mm with the further placement of mines in it;

- installation of a detonating capsule;

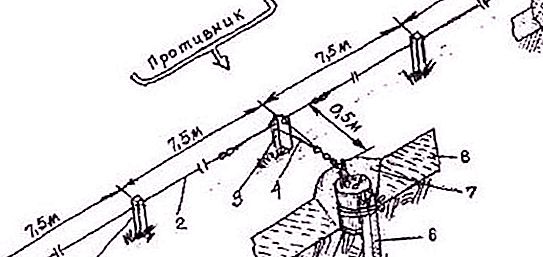

- installation of a metal peg at a distance of 50 cm from the mine;

- cable fasteners with carabiners for wire brace;

- installation of one wooden peg with the passage of wire through it the entire length; the end of the extension must be attached to the top of the second peg; it is imperative that the wire between the wooden stakes sag a little - 20-30 mm is enough;

- unscrewing the protective cap covering the mine igniter;

- bringing fuse checks to a combat state;

- connection with the help of a carabiner of a prepared wire extension with a fuse pin;

- disguising the installed mine.