Gear reducer is designed to change the frequency and direction of rotation of the shaft. It transfers power from the engine to the desired machine unit, operating on the principle of rotational motion. In any power unit you can find gearboxes of different types, depending on their design and purpose.

Gear applications

The scope of gearboxes is wide - from mini-drives in medical technology to power plants of factory value. They found a place in agriculture, metallurgy, coal industry, engineering, shipping and automobiles. Gear reducers are operated in different climatic conditions - indoors, outdoors, in heat, cold and even in arctic conditions.

The use of gear systems is due not only to the ability to change the direction of movement of the shaft. With the help of gears, the rotation speed increases and decreases, the torque on the shaft changes (more often increases).

Design Classification

There are three types of gearboxes according to the principle of energy transfer - worm, wheel and wave. By the type of layout and parts used, worm, chain and gear reducers are distinguished. Hybrid options are common. In their design there are gears and chain transmissions at the same time.

Gear-based mechanisms are available in two types - with a cylindrical and bevel gear, depending on the shape of the working element. The latter transmit rotation at an angle of 90 ° relative to the axis of the engine.

Design and specifications

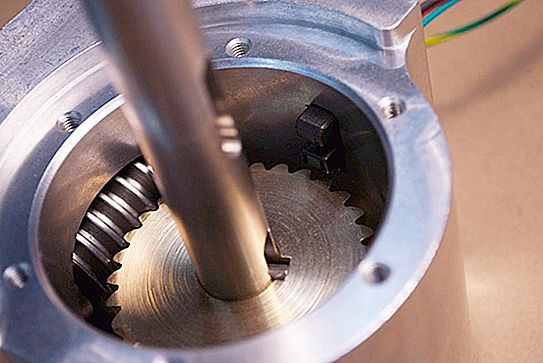

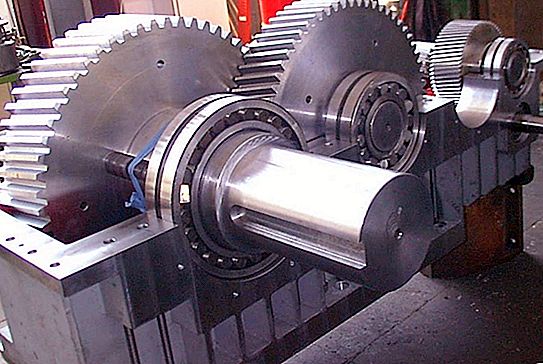

The design of any gearbox is simple - it is a set of gears, shafts, bearings with a lubrication system installed in a common closed housing. Hybrid transmission devices are more complex - chains, belt drives, and worms are placed in their housing. The system of gears and shafts constitutes a gear transmission, and each pair of them in one housing determines the number of gear ratios. In gear-chain gearboxes, a chain with two stars constitutes an additional step.

The main characteristics of any gearbox are its efficiency, the number of stages and gear ratios. The efficiency depends on the ratio of power on the input and output shaft. The greatest efficiency is possessed by cylindrical gears, as the simplest with minimal power loss. The gear ratio is measured by the ratio of the shaft speeds at the input and output of the mechanism, and for each stage the eigenvalues are calculated according to the same principle.

The combination of gear pairs of different rotational speeds and their number in one housing allows you to get the specified characteristics on the output shaft - power, speed and direction.

Features of the cylindrical device

A cylindrical gear reducer is the most common type used in mechanical engineering, metallurgy and agriculture. Straight and helical gears are structurally simple and reliable, easy to operate. Its design, if necessary, becomes complicated, becoming reversible - for use in cars or garden equipment.

The spur gear has an efficiency of 98-99% efficiency and low heat dissipation. In this case, the gears are capable of transmitting large powers to the target assembly of the mechanism.

Helical gearboxes are available both for industry and for private purposes. You can buy a separately sold gearbox and use it on any home-made device.

The disadvantage of a gear cylindrical device is the difficulty of maintenance in comparison with chain transmissions of the same power and high noise during operation.

Household use

The gear reduction gear for low power devices (up to 10-15 horsepower), available in stores, is actively used in gardening equipment - in cultivators, seeders. Craftsmen involved in mechanization of labor, using purchased or home-made gearboxes, make walk-behind tractors for plowing the garden. This is one of the most common gear applications in the household, not counting cars.

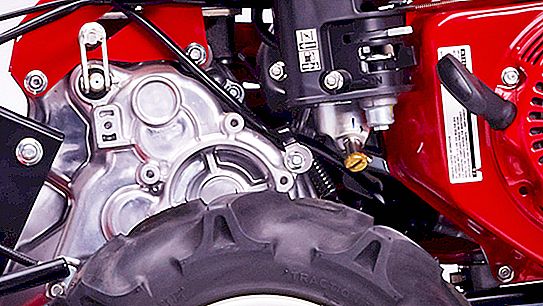

Motoblocks with gear

The motoblock with a gear reducer is designed for plowing and cultivating a small area of land. Depending on the size of the plot, the power of the mechanical plow is selected, reaching 10-15 liters. with. The operation of a mechanism of such power is not possible in a belt or chain drive. After all, gears withstand much greater loads.

A reduction gearbox, mounted on powerful motoblocks, can be made independently from spare parts for automobile differentials and gearboxes or bought in a store from a number of produced for garden purposes.

Mobil-K companies or Krasny Oktyabr-Neva CJSC produce gear-type cylindrical gearboxes for transmission of Russian-made motoblocks. These devices are available as spare parts for cultivators, so they are not always interchangeable. This limits their installation on another model of walk-behind tractor.

Motoblocks with a gear reducer and disk clutch gained popularity due to gear shifting without stopping the pulley. But such designs are more complicated and more expensive.

The most widely used are hermetic gearboxes with an oil bath and an aluminum housing. Due to their low weight and simplicity of design, such mechanisms are practically maintenance-free. There are non-separable models that change upon failure and cannot be repaired.