Plastic is so deeply “ingrained” into our reality that we simply cannot imagine our existence without it. Think about how many things and objects made from this synthetic material surround us in everyday life. On the other hand, more and more today they talk about the dangers of plastic bottles, dishes and other products, both for human health and the environment. This article describes in detail about plastic, its varieties and markings, as well as about the possibilities of processing plastic products.

What is plastic

The names “plastic” and “plastic” come from the word “plastic”. This means that this material as a result of heating is able to form a certain shape and maintain it after cooling. Under the general name "plastics" is meant a number of organic materials, which are based on high molecular weight compounds - polymers.

The production of synthetic plastics is based on the polymerization and polycondensation reactions of certain substances. It can be benzene, phenol, ethylene or acetylene. The set of mechanical and physical properties of plastics is approximately the same as that of metals (density, hardness, brittleness, heat resistance, etc.).

In general, plastics are characterized by low strength, relatively low density (not more than 1.8 g / cm 3), and high resistance to moisture, acids and some solvents. When heated, they usually decompose. Plastics are much more fragile than most metals.

A bit of history

The year of birth of plastic should be considered the 1855th year. The "father" of this synthetic material is the Englishman Alexander Parks. True, he called him parkesin.

Parkesin was obtained by Parkes from cellulose as a result of treatment with the latter with nitric acid and a solvent. The revolutionary new substance is called "ivory." Parks planned to launch Parkesine mass production and established his own company, Parkesine Company. However, the company quickly went bankrupt, as the quality of its products was not so good.

For commercial purposes, plastic began to be used only after the Second World War. Mass production of plastic bottles was established in the 1960s. Very quickly they became wildly popular with both consumers and manufacturers.

Plastic Product Manufacturing

Today in the world there are many enterprises that produce sweet drinks, mineral water and alcohol. All of them, of course, need a huge amount of appropriate plastic containers. How do plastic bottles do? How complicated is this manufacturing process?

The raw material for the production of plastic bottles is granular polyethylene terephthalate (abbreviated as PET). The substance is loaded into a special machine (injection molding machine), where a preform (preform) with thick walls and a formed neck is obtained from it. Then it is placed in the desired shape and a steel tube is introduced there. Through it, air is fed into the preform under high pressure, which evenly distributes the melt along the walls of the mold.

Further, the form is cooled. The final stage is the removal of all defects obtained when the plastic flows over the cracks of the mold. After that, the finished bottle is removed from the mold and sent for sorting. It is important to note that in the manufacturing process of plastic bottles, about 25% of the product goes into marriage and is recycled.

Another key feature of plastic production is its energy intensity. So, for the manufacture of one thousand plastic bottles, you will need to spend up to 10 kW of electricity.

The harm of plastic bottles

Excessive cheapness and ease of use of plastic turned to other significant problems for humanity. The harm from plastic bottles and other products from this material is colossal. Moreover, both for ecology and for the health of the human body.

Almost all plastic containers for food products contain various harmful substances and toxins. Most often it is phthalate and bisphenol-A. Through food and drinks, they enter the digestive system and are carried by blood throughout the body. The toxins contained in plastic food containers can affect our body as follows:

- Knock down hormonal balance.

- Accumulate in the liver, gradually destroying its cells.

- Reduce the defenses of the body’s immune system.

- Deteriorating heart and circulatory system.

- They provoke the development of cancer cells.

Many people ask: is it possible to store alcoholic beverages (for example, beer or wine) in plastic bottles? The answer is unequivocal: no. Alcohol is an active chemical medium. Alcohol, being in prolonged contact with polymers, begins to interact with them. The result of this interaction you yourself will feel when you try wine from plastic: in the drink there will obviously be synthetic “notes”.

The same thing happens with beer. In plastic bottles, methyl alcohol draws in all the harmful toxins, turning into a real "organic solvent." Plastic containers cause maximum damage to the body when it heats up. So, for example, polystyrene (one of the varieties of plastic) when heated to 35-40 degrees turns, in fact, into poison. By the way, in many European countries you will find it difficult to find beer in plastic for sale.

Thus, alcoholic beverages are best stored in glass or porcelain dishes. Plastic bottles for water (non-carbonated) are relatively harmless and harmless. However, they are categorically not recommended to reuse such containers.

The harm of plastic bottles and packaging for a person depends on the labeling of the product itself. This question is worth dwelling in more detail.

Marking of food plastics

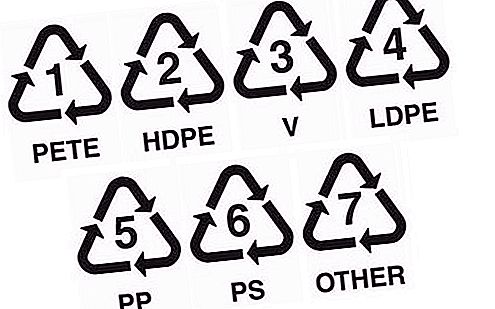

You are not ready yet to completely abandon the plastic? Then learn to choose products from it with minimal damage to your health. The special marking of food plastics will help you with this. It has the form of a triangle, consisting of three arrows. The figure placed inside it, as well as the letter symbols under the figure, will tell you what type of plastic a particular product was made of.

So, take a plastic container or bottle and carefully examine it. It must have one of the following characters:

- No. 1 PET (or PETE) - polyethylene terephthalate. Relatively harmless. The most common type of plastic used in the bottling of soft drinks and liquid consistency products. Recyclable.

- No. 2 HDPE (or PE HD) is high density polyethylene. Plastic with a low level of danger, although the possibility of the release of formaldehyde, a substance that provokes genetic disorders and changes in the hormonal background, is not ruled out. Often used in the manufacture of bags, disposable tableware, containers for milk and dairy products.

- No. 3 PVC (or V) - polyvinyl chloride. Technical plastic used in the manufacture of plastic windows, pipes, furniture parts, etc. Not suitable for food use.

- No. 4 LDPE - low density polyethylene. Garbage bags, CD-ROMs, linoleum are made from this cheap and relatively safe plastic. For humans, it is harmless, but does significant damage to the environment.

- No. 5 PP - polypropylene. Of all types of plastics, it is considered the safest. Often they make children’s toys, medical supplies and food containers.

- No. 6 PS - polystyrene. It is used in the production of a wide range of products - meat and vegetable trays, sandwich panels, cups for yogurt, etc. May release styrene, which is considered a dangerous carcinogen. Experts recommend minimizing the use of this type of plastic.

- No. 7 O (or OTHER) - all other types of plastic (in particular polyamide and polycarbonate). With strong heating, they can secrete bisphenol-A, a rather dangerous substance that provokes hormonal disruptions in the human body.

Plastic and ecology

Plastics is perhaps one of the most controversial materials. On the one hand, it is a very cheap and convenient material, which has found wide application in medicine. Plastic products help save thousands of lives every day, and that's true. But on the other hand, plastic waste in recent decades has been rapidly polluting our planet. Here is a list of seven impressive facts that will help you realize the scale of this environmental issue:

- The complete decomposition of one unit of plastic takes up to 500 years.

- Up to 40% of all plastic waste is bottles.

- When buying water in a plastic bottle, approximately 90% you pay exclusively for containers.

- In Europe, only 2.5% of the total mass of plastic is recycled.

- In the US, this figure is 27%, and this is still the highest figure in the world.

- 13 billion plastic bottles are produced worldwide annually.

- Each year about 150 tons of various plastic waste are thrown into the ocean.

Garbage Islands: Recognize the scale of pollution

Pay particular attention to the last item. In 2014, environmentalists estimated that there were about 270 thousand tons of plastic waste on the surface of the oceans. And in 2017, Dr. Jennifer Lavers discovered that the coast of the uninhabited Handerson Island, located in the Pacific Ocean, is literally littered with garbage. The pollution indicator here reaches 670 objects per square meter of territory. Both figures are amazing!

There is so much plastic debris in the oceans that they have already formed several “spots” or islands: two each in the Pacific and Atlantic oceans, and one more is located in the Indian Ocean. The largest of them is the so-called Great Pacific Garbage Patch (Eastern Garbage Patch). Sometimes it is also called the "Eastern Garbage Continent."

The Pacific garbage spot is localized between approximately 35 ° and 42 ° north latitude and between 135 ° and 155 ° west longitude. It occupies a relatively stable stretch of the ocean with an area of 700 thousand square kilometers (this is approximately comparable with the area of Turkey). The garbage island was first discovered in 1988. Whirlpools of the Pacific system of currents bring here garbage and waste from the entire northern part of the Pacific Ocean, including the coastal regions of the USA and Japan.

Of course, a garbage stain is not a solid carpet of household waste. According to studies, at least 5 mg of whole or partially decomposed plastic falls on one square meter of water surface. Jellyfish and fish often take it for food, confusing it with plankton. Suffer from plastic pollution of the oceans and birds. So, in the stomachs of dead albatrosses, bottle caps, lighters and other “benefits” of human civilization are often found.

The rejection of plastic and polyethylene: environmental trends of the XXI century

The accumulation of plastic waste in the environment negatively affects the habitat of many animals, infects water and soil. Moreover, two things are considered the main enemies of our planet - plastic bottles and disposable plastic bags.

Measures aimed at reducing the plastic pollution of the Earth have long been introduced in various regions and countries. First of all, they are aimed at collecting plastic bottles, sorting and processing them, as well as at a general reduction in the consumption of plastic products in the world.

According to environmentalists, every year, humanity uses about 4 trillion plastic bags for its domestic needs! As of 2017, about 40 countries around the world have completely abandoned their production and operation. Among them - and quite "advanced" in environmental terms, the state (France, Denmark, Australia, Finland), and, surprisingly, third world countries (for example, Rwanda and Tanzania).

But, one way or another, mankind is not yet ready to completely abandon plastic and polyethylene. Therefore, the centralized reception of plastic bottles (and other waste), as well as their sorting and further processing, plays an extremely important role in each country. So, in the USA, special containers for collecting plastic products are installed at almost every garbage collection point.

Plastic recycling

As mentioned above, the period of complete decomposition of plastic containers can last up to 500 years. It is quite obvious that our planet can turn into one global dump even before it has time to completely “digest” all those deposits of plastic that humanity has already produced.

That is why industrial processing of products from this material is so important. In addition, PET raw materials can be reused an unlimited number of times. There are also special technologies that make it possible to obtain automotive fuel from plastic raw materials.

But most often, plastic is processed into the so-called “granulate”. And this process includes several successive stages:

- Reception of plastic bottles and other containers, as well as their sorting.

- Cleaning PET products from debris and dirt (an extremely important stage, because poor-quality removal of contaminants and glue from bottles adversely affects the quality of the final product).

- The use of crushing equipment and the transformation of plastic into small crumbs.

- Re-cleaning (rinsing) the plastic chips from dirt.

- Drying and heat treatment of crumbs (agglomeration).

- Granulation of the obtained material to particles of the desired size.

Next, we will get acquainted with the main and additional equipment for plastic processing.

Necessary equipment

For the first stage of plastic processing (sorting and pressing), it is necessary to have only two units:

- Conveyor (or sorting table).

- Press machine.

Labels, caps and bottle rings in this case, as a rule, are removed manually.

For further processing, a wider range of equipment is needed. It:

- Vibrating screen (removes debris and particulate matter).

- Conveyor (sorts the feedstock).

- Crushing machine (crushes plastic into small fractions).

- Centrifuge (dry plastic).

- Extruder (processes plastic crumb into granulate or another product of a given shape).

The list of additional equipment includes:

- Dispenser.

- Rinse bath.

- Friction auger.

- Capacity for soaking fleks.

The minimum cost of one processing line is about 4 million rubles. Domestic equipment is much cheaper (about 1.5 million rubles). However, it is more often subject to breakdowns and is characterized by lower productivity. Leading companies in the production of equipment for plastic processing: Herbold, Sorema, Redoma, Shredder.