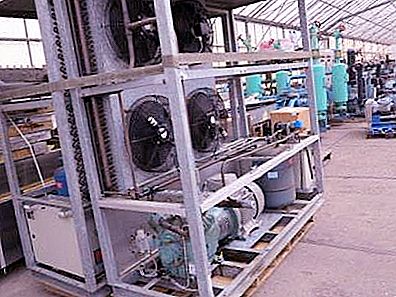

The operation of each refrigeration unit is provided by special units and control systems. The functions of the main part of the equipment are compression, cooling and vapor condensation. Condensing unit is a special-purpose installation that changes the state of the refrigerant depending on the ongoing process.

The selection of this equipment depends on the ambient temperature, the capacity of the camera and, directly, the purpose. There are several types of installations: air-cooled and water-cooled.

The device is driven by a motor (electric motor). Condensing unit with a small capacity can be used in industrial refrigerators, air conditioners, domestic refrigeration appliances.

Small devices with low noise have the following advantages:

- Possibility of use in small rooms.

- A simplified installation and maintenance process.

- Small size.

- Strength and durability of the structure.

Component parts of the unit

The main part of any refrigeration unit comes ready-made from the manufacturer. Pipes and fittings that experience high pressure are tested before assembly. Wiring diagrams and the control panel are also tested. Upon receipt of the apparatus, the integrity of the packaging and the housing should be checked. If all the characteristics are normal, you can connect the compressor-condensing unit to the refrigeration unit.

The basic composition of the apparatus:

- High pressure switch. The purpose is to control the cooling system (fans).

- Control Panel. The latter consists of a thermostat (responsible for the automatic start / stop of the compressor), a fan speed controller. The engine operation process is responsible for turning the heater on and off.

- Dual relay (high and low pressure). This device works in emergency situations.

- Compressor. This unit is filled with oil, as well as a tenom for heating it. Pressure sensors are installed on the suction and discharge lines of the refrigerant.

- Vibration and noise isolation.

Specifications

For small shops, gas stations and other low-budget businesses, relatively “quiet” condensing units are used. They emit noise and vibrational vibrations that are permissible during operation in the residential sector.

The purpose of these devices is to create an artificial lowering of the operating temperature in a small commercial and air-conditioning equipment.

The units operate on explosion-proof refrigerants (R22, R404A, R407C, R507). Moreover, these liquids do not ignite or destroy the planet’s ozone ball.

Low-temperature performance ranges from 3.8 to 17.7 kW, depending on the fluid selected.

The control is performed by starting and stopping according to the signals of external devices and sensors (for example, a thermostat). When the required cold level is reached, the compressor is automatically turned off, and when the set temperature rises, it turns on.

The condensing unit has comprehensive protection: from overheating of the windings, fans, high pressure, improper voltage in the network.

Stages of design and development of units

- First of all, it is necessary to obtain the parameters: latitudinal zone, temperature range, volume of the room or chamber.

- The next step is the calculation of power consumption.

- Next, related equipment is selected, working schemes and drawings are developed.

- To install a refrigeration condensing unit, a frame or suspension system is designed.

- On the selected frame, all the necessary devices and related accessories are installed.

- Next, the previously tested pipeline (copper or steel) is sealed.

- Lastly, an automation and control system is connected.

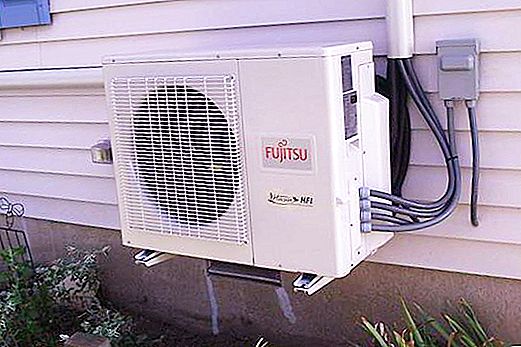

Compact devices for cooling

To obtain low temperatures in small devices, compressor-condenser AK units are used. The latter are ideally suited to work as part of mobile devices, air conditioning systems, as well as for individual devices to quickly lower the temperature.

The main characteristics of AK are:

- Mains supply: 230/400 V.

- Operating temperature range: 35-60 ° C.

- Power consumption: 1-30 kW (for medium temperature) and 0.5-20 kW (for low temperature).

- Refrigerating capacity: 2-70 kW.

- Refrigerant used: R404A, R134A.

Economical appliances

To maintain temperatures during storage of products with a short shelf life, medium-temperature compressor-condenser units are used. Such devices are capable of maintaining a level from -5 to +14 (◦С).

Monoblocks are designed for small cameras that can be operated at ambient temperatures up to + 40 ° C. In this case, the compressor unit and cooler are installed in one unit. The requirements for working in such conditions are: thick walls of the room (from 200 mm), the presence of additional equipment.

On large areas, split systems are used. In the latter, the condensing unit is located separately from the cooler.