In modern conditions, not all countries can afford the purchase of new armored vehicles. Yes, and wealthy states have not purchased lots of several hundred pieces for a long time, limited to orders for 40-50-70 pieces of equipment. Therefore, the requirements for the manufacturer are extremely high. Ukrainian BTR-3 is one of those models that have customers, even in the current difficult economic realities.

Development start

The construction of new equipment began in 2000. The first machine was not created on an initiative basis, but for a competition in which the selection of military equipment for the UAE marines was carried out. It is not worth considering that the BTR-3 is something really new, since it was made on the basis of the old BTR-80. More precisely, on the basis of the BTR-94, which is a logical development of the "eightieth" model. This machine was developed at the Kharkov Machine-Building Plant. The design of the new model ended in 2002.

Four large defense concerns from the UAE, Germany, the USA and Ukraine itself participated in this process. About a dozen Ukrainian companies are engaged in the production of components. The project turned out to be a kind of "international".

Production

The production of the new BTR-3 hulls is carried out not from scratch, but by reworking the old BTR-70 and BTR-80, a huge amount of which was donated to Ukraine after the collapse of the Soviet Union. Assembling a new armored car is carried out at the Kiev Armored Plant. Experts suggest that the operating costs for one "three" are not more than five thousand hryvnias per month, which is several times less than the costs of maintaining one BTR-4.

Design defects

As of 2015, it was reported that the country mastered the production of at least 90% of components for new equipment. This made it possible to reduce dependence on supplies and make the production of armored personnel carriers more cost-effective.

In the recent past, the management of the Kiev factory reported that since the start of production and at that time, almost 800 different changes had already been made to the design of the machine, which corrected the deficiencies identified during operation. In addition, it was possible to significantly increase the manufacturability of production, only having achieved the correct location of the welds. Last year, intensive work was begun to study the possibility of installing German MAN engines in an armored personnel carrier.

It is reported that in early November 2015, Thailand achieved the signing of an agreement according to which it can independently produce BTR-3 and its components on its territory. It is unclear, however, how Thais are going to make buildings. Either they will have their own foundry building for BTR-3 open, or they intend to purchase old BTR-70/80 from Ukrainians.

Design Features

Given the origin of the machine, one should not be surprised at its layout with the front location of the control compartment. The airborne and combat squads are located in the middle of the armored personnel carrier, and the engine compartment in the rear. The BTR-3 armored personnel carrier directly borrowed such a layout of compartments from its "ancestors".

Like them, this model is able to force water barriers under its own power. For movement in this case, a jet engine mounted at the stern is used. Much has been done for the convenience of the driver. So, to start forcing a lake or river, he does not need to leave his workplace: shields for reflecting water and a pump for pumping out its excess are switched on directly from the cabin.

Thus, in a full-time crew only two people should be listed: directly the driver-mechanic and the operator of the combat module. At least eight fighters in full ammunition are placed in the airborne compartment, who can enter the car and leave it through double-wing hatches cut in the lower part of each side. The classical scheme is used: the lower part of such a door forms a convenient ledge, and the second partition, reclining in the direction of travel, covers the landing from possible shelling from individual small arms. For emergency situations, hatches on the roof of the armored car are provided.

There is a standard installation for air conditioning, as well as an automatic fire extinguishing system in the engine-transmission compartment.

Degree of security

But this point is most interesting to consider. The fact is that the Ukrainian side is positioning this armored car as the most protected, comparing it with almost a full tank. How justified is this approach and how is the BTR-3, the technical characteristics of which we are considering, capable of withstanding various weapons?

This is the first Ukrainian-made armored car in the construction of which differentiated armor was used: steel protects the crew from the damaging effects of bullets, and the Kevlar loot is designed to brake and hold fragments. As we said, the hull is assembled from old Soviet-made armored personnel carriers by welding additional armor plates from rolled sheet steel. With the exception of the stern, they are all set with rational angles of inclination, which increase the likelihood of a rebound and provide increased security for the crew of the machine.

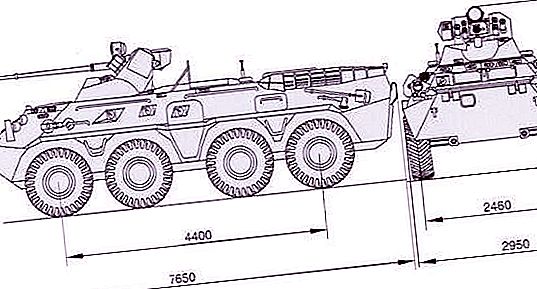

The BTR-3 case, the drawings of which practically in all respects repeat the characteristic features of the BTR-80, is notable for its smooth contours. According to Ukrainian designers, this was done to facilitate overcoming water barriers. Again, there is information that, at the request of the customer, an airborne compartment with a height of 150 mm can be mounted, which facilitates the entry and exit of soldiers, as well as the evacuation of the wounded from the battlefield.

Mobility characteristics

To simplify control and reduce the load on the driver, a powerful hydraulic power steering is structurally provided. Four (!) Front wheels are steering, which significantly improves the maneuverability and maneuverability of the car. There is a centralized system for indicating tire pressure and a mechanism for controlling it, which allows you to quickly adjust its performance without leaving the machine. This is especially convenient if you immediately need to overcome sections of the furnace and wetlands.

Powertrain and transmission

Currently, the German Deutz BF6M1015 motor is installed on the BTR-3 Dozor, delivering power up to 326 liters. with. The machine is equipped with a fully automatic transmission Allison MD3066. There is a more budget option when an armored personnel carrier receives a UTD-20 engine, developing a capacity of about 300 liters. with. But it is not in great demand either in the country itself or among foreign customers, since the mobility of such equipment is not satisfactory.

MTU 6R106TD21 engine is installed on the latest and new model, internal volume is 7.2 liters. This motor can already deliver power up to 325 liters. with. And this time, manufacturers decided to mount a fully automatic transmission Allison 3200SP. It is reported that by the beginning of 2015, a (theoretically) prototype of a fully Ukrainian automatic transmission was ready. Most likely, if this project will be implemented in the current economic realities, then we are only talking about licensed production of a foreign model.

Undercarriage Specifications

BTR-3E1 is equipped with bulletproof French Michelin tires [9]. The tires are diagonal, tubeless, variable pressure and dimension 365/90 R18 or 335/80 R20.

What is armed with the new armored personnel carrier

Specifically for this technique, the KBA-105 Flurry combat module was developed, the main striking force of which is the modern 30-mm gun of the ZTM-1 model. A 7.62 mm KT-7.62 machine gun works in tandem with her. What can the BTR-3 crew (a modern armored personnel carrier after all) do when meeting an enemy tank? For this purpose, the machine is equipped with two launch containers ATGM 9M114M "Competition-M". To attack the infantry or repel its attacks, a 30-mm automatic grenade launcher can be used.

The OTP-20 complex is responsible for fire control and stabilization of the main gun, the design of which includes the latest gun stabilizer SVU-500. Its use has significantly improved firing accuracy even at long distances.

Another version of the combat module

There is an option to equip an armored car with the BM-3M Sturm combat module. It differs in the stabilization of the entire arms block in two planes at once. This system was developed under the direct supervision of M. D. Borisyuk. As in the previous case, the basis of the module is an automatic 30-mm gun of the ZTM-1 model (ammunition - 350 rounds), as well as a 7.62-mm CT machine gun with ammunition of 2000 rounds. On the right side of the module, a Launch Barrier with four anti-tank missiles is installed, and on the left there is a 30-mm KBA-117 (automatic grenade launcher).

As in the previous case, the OTP-20 complex, which is fully integrated into the Barrier ATGM control systems, is responsible for guiding the target and accuracy of firing. The SVU-500 acts as a weapon stabilizer. Since stabilization is carried out simultaneously in two planes, the BTR-3 Guardian (armored personnel carrier) can conduct effective fire immediately, without wasting time stopping and aiming. The tower also has small mortars (81 mm) designed to eject smoke clouds "Cloud".