Providing tools and assemblies with a pneumatic installation gives many advantages to the working process. The supply of compressed air involves the formation of power action, which eliminates the need to use network power sources. Compressors act as generators of effort, while possessing different technical and physical characteristics. The segment of domestic models of this equipment is inferior in some respects to foreign equipment, but there are companies offering optimal solutions in terms of price and quality. These include the manufacturer Interskol. The compressor of this brand combines the reliability of the design, new technologies, wide functionality and modern ergonomics. However, the family of the company offers several compressor options with an emphasis on different operational qualities.

Features of Interskol compressors

In one niche with manufacturers of the Fubag, Abac and Metabo level, not every Russian enterprise will be able to surprise something. Nevertheless, engineers and designers of Interskol develop durable structures that are notable for ease of operation and low price. Compressor balancing is the main concept of the company. This problem is solved in various ways. For example, to ensure the reliability of the units, corrosion protection coatings are used (the receiver is being processed), valves are integrated in case of exceeding the pressure indicator, and housings with increased strength are installed. So that the Interskol air compressor does not impede the physical handling and control processes during use, the creators provide for the presence of supporting elements in the form of legs and wheels.

Damping anti-vibration protection is also used to increase stability, but in general, designers are trying to minimize the dimensions of the equipment without losing performance. Added to this is the ability to integrate measuring instruments to monitor compressor operating parameters. A pressure gauge has long been a mandatory component, and in modern versions, the Interskol compressor is also provided with a pressure switch for changing pressure indicators.

Key compressor specifications

According to the main operating indicator in the form of the volume of air supply, domestic compressors can arrange both an ordinary home craftsman and an industrial workshop. In medium versions, oil belt units provide about 150-200 l / min. For more responsible tasks, you can look at the technique that works with indicators of 400-500 l / min. As for the average working pressure, it is 8-10 Bar, depending on the type of installation and its power potential. Here the parameter of the rated power of the Interskol engine will be significant. The compressor is provided with electric power plants of 1.5-3 kW. Accordingly, the higher the performance, the more powerful the electric motor will be. The volume of the receiver, which can accommodate 25, 50, and 100 liters, is also interconnected with these parameters.

Types of Interskol compressors

The company mainly produces coaxial compressors, which are also called reciprocating compressors. The features of such units include the combination of mechanical components and an electric motor into one system. Both the piston and the power plant operate in the same high-speed mode, which allows to reduce the size of the compressor. Also, developers rely on oil and belt models. Oil-free devices differ from oil-free devices with a longer service life, but their air quality is less high. Lubricant particles can enter the air stream, which negatively affects the operation of the pneumatic tool. But on the other hand, the Interskol oil compressor is optimally suited for semi-professional fields of operation. He effectively manifests himself in auto repair shops, on production lines and in the maintenance of construction equipment. Belt modifications, thanks to the features of the drive, are more resistant to wear and damage, but have slightly reduced performance indicators.

Model KV-240/25

An entry-level compressor with low power and modest performance. The equipment has a coaxial device with a piston and provides for oil lubrication. With a power potential of 1.8 kW, the unit is capable of delivering air with a volume of 130 l / min. This is enough to maintain the function of the sandblasting apparatus, which is planned to perform cleaning or painting surfaces. Users note a good ergonomics, which is endowed with this Interskol compressor. Reviews emphasize a comfortable handle for the operator, and wheels, complemented by rubber racks.

Model KV-430/50

The average performance compressor, which is considered one of the most popular in the family. The model belongs to the category of belt oil units, from which it follows that the emphasis is on increasing durability by reducing performance. As the manufacturer indicates, this modification has an operational resource of about 7, 000 working hours before repair. The volume of the receiver is 50 l, and the productivity is 430 l / min. What is more important, the Interskol KV-430/50 compressor is made of materials improved in working properties. For example, a group of cylinders is made of honed cast iron, and the closures are based on polyurethane.

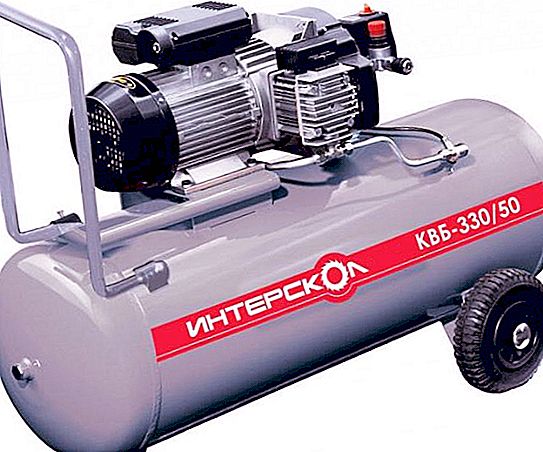

Model KVB-330/50

One of the most expensive compressor stations in the company’s family. This is an oil-free piston unit with many design features. Engineers used pistons without a functional edge, and the cylinder walls were treated with alumina. The result was an optimized technical basis, ready to work with frequent starts in conditions of temperature extremes. In addition, this model can be considered as a universal installation. The developers have provided two quick-detachable connections, which makes it possible to use several consumers at the same time. But before that, it is important to make sure that the equipment being serviced complies with the requirements of the Interskol donor station. The compressor operates at a pressure of 10 bar and provides a flow volume with an intensity of 330 l / min.

What to consider when choosing a compressor?

In addition to calculating basic performance indicators, it will not be out of place to initially determine the equipment bundle. Depending on the nature of the operation, additional fittings, hoses, filtering devices and adapters may be required. A lubricant should also be provided in advance. In particular, the Interskol 430/100 compressor belongs to oil technology and in the process of working with large volumes it will need stable corrosion protection. It is desirable to provide it with mineral oils with modifiers that increase the physical qualities of the composition. As an addition, you should also take care of measuring devices that will allow you to keep under control the possible equipment loads.