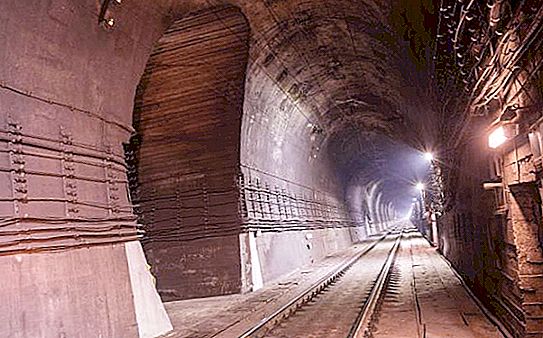

The Severomuisk tunnel is located in the Republic of Buryatia. Commissioning took place in 2003. It is the longest railway track laid through the rocks in Russia. The length is 15 343 meters. The name of the tunnel was on behalf of the ridge through which the highway passes. The degree of difficulty in construction and tunneling is considered the most difficult in the world. The construction was carried out for twenty-six years, the foundation was laid at a time when the whole region was a lifeless rocky space. Climatic conditions were harsh, the average temperature in the area of the North Mui Range varies in the region of -50 degrees Celsius. It was necessary to import not only equipment, it was necessary to build residential villages and infrastructure to ensure the normal life of the staff.

Difficult plot

The Severomuisk tunnel was the last point that connected the Baikal-Amur Railway into a single whole. The idea of building a railway along the Amur River arose in tsarist Russia, but the amount of funds and work required to carry out the project, even with rough estimates, turned out to be exorbitant at that time. The idea hung in the air, it got its real shape only in 1938, when the laying of the railway began. The first employees were prisoners. Construction was carried out intermittently, a grandiose scale and the movement of the masses on the BAM began in the 70s of the last century. Volunteers from all over the Soviet Union traveled to lay the railway.

The most difficult part of the route turned out to be the North Mui Range. In Transbaikalia this is one of the most beautiful, but harsh places. The rock formation consists of granite-slate rocks, glaciers are located on its slopes, the highest point of the ridge reaches 2561 meters. There is practically no vegetation on the rocks, tectonic shifts after the earthquakes were not fully explored, and seismic activity was unpredictable. Tunneling has become a challenge for engineers and builders.

There were many projects that offered solutions for the passage of the site. From the most insane: to blow up the ridge and thereby clear the way, to the most decadent - to abandon and not build, because it is impossible. After hesitation and deliberation, it was decided to go through the ridge. Preparation for the passage began in 1975, the main work fell on the 90s and only in the next century the Severomuisk tunnel was put into operation. The date of construction, or rather, the completion of construction, was March 30, 2001, and the first trains started moving on December 5, 2003.

Project development

The general developer of the project was Lenmetrogiprotrans OJSC. According to the project, construction was carried out from two points: western and eastern, two teams of drifters walked towards each other. The work was carried out by two organizations. The company Bamtonnelstroy OJSC was engaged in the construction of underground facilities, and Nizhneangarsktransstroy OJSC was building ground facilities. At the time of the approval of the project, no one knew what difficulties and surprises they would encounter. In the process, changes were made to the original plan, twice the work was stopped due to landslides and landslides.

The passage of the tunnel turned into human casualties, according to various sources, from 30 to 57 people died during the construction and liquidation of accidents. A monument was erected in their honor near the entrance to the tunnel. Over the entire construction period, several dozen machines from all over the world were tested, a unique technology for fixing the soil in the tectonic fault zones by a chemical method was developed and introduced. This completely new invention helped the tunnels to successfully build a tunnel in the most difficult and unpredictable conditions of granite rock breaks.

To ensure non-stop work for builders, two workers' villages were built: at the western entrance of Tunnel, and at the eastern Severomuisky. To date, the village of Severomuisky has remained active, where Russian Railways employees provide maintenance of the tunnel.

Features

At the time of the commencement of work, the geological condition of the ridge was unknown, therefore, exploration work took place simultaneously with the construction. To reduce risks, in parallel with the main branch, the construction of a reconnaissance adit was started. Its development was several hundred meters ahead of the main tunnel, and this provided information on the condition of the rock. The branch line was developed at a distance of 30 meters from the main construction; in size it is sufficient for the passage of the subway train. Passages erupted from the reconnaissance tunnel into the main channel, which facilitated work and ventilation.

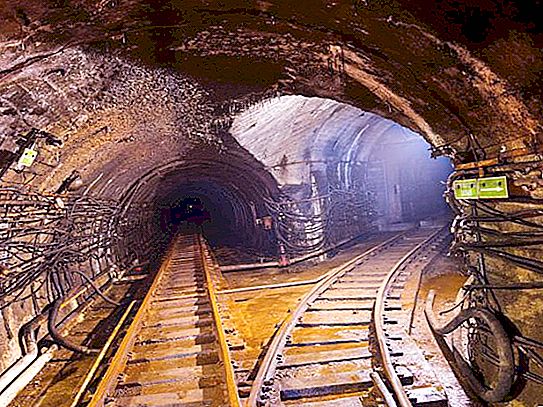

The construction of the structure took place in a seismically active zone, where earthquakes reach 9-10 points on the Richter scale, the geological conditions of the passage showed four tectonic faults. Simply put, these are rock break places filled with stones, sand and water, their width ranged from 5 to 900 meters. Through the breaks, water in the amount of hundreds of cubic meters per hour constantly flowed. Part of the tunnel passed through permafrost zones, hot water was used to build these sections. A surprise was the presence of radioactive rhodonium gas, which escaped from the bowels of the tunnel when it was laid; its concentration was three times higher than the permissible norms, which led to the exposure of workers. For this they paid a decent allowance, which the diggers dubbed "coffin money."

The Severomuisk tunnel in Buryatia, according to the project, suggested drilling exploratory wells every 0.5 kilometers, but, deciding to reduce the cost of work, they were drilled in increments of 1 kilometer. This way of saving turned into several disasters, which led to human lives, stopping work in connection with collapses, floods and other things.

Construction

The Severomuisk railway tunnel survived two long construction stops. The first occurred in 1979, when mine penetration came across a quicksand in a granite monolith. Mining workers have not encountered such a phenomenon either before or after. Water under high pressure broke through the rock and, carrying stones, sand, mud streams, swept everything in its path: several workers were killed, a twenty-three-ton loading machine was washed away. Restoration work and conservation of the rock fault site were required.

To eliminate the cause of the collapse, concrete was poured into the fault; drying lasted two years. During this time, thirteen thousand tons of collapsed rock were recovered, and additional exploration work was carried out. As a result of reconnaissance, an underwater lake was discovered in the area of the passage of the tunnel. To solve the problem of excess water flows, an innovative solution was required, no one has encountered a similar phenomenon in world practice.

Resumption of work

Fracture points were strengthened by chemical fixation of the soil, the inner lining of the tunnel was carried out by cast-iron tubing, metal structures. An additional layer of concrete was poured on top of this cladding, which improved waterproofing and gave enhanced support to the tunnel arch. Thus, the critical zones of the structure received several layers of “pipes” constructed and moving independently of each other. In a seismically active zone this increases the level of safety and stability of the building.

They again started sinking in 1981, for this they had to break through a concrete cork. In the process of further passage, all detected faults were filled with concrete through drilled vertical shafts. Foreign experts with a worldwide reputation were invited to work on the project - no one agreed. During the construction, the most advanced equipment of the time from Japan, the USA, and Germany was used. Professionals of foreign companies, getting acquainted with the situation, gave only one piece of advice - quit and start in another place. To ensure continuous operation, the delivery of equipment, dump and removal of the rock was required, a siding was needed, since it became clear that the construction would be delayed for an indefinite period.

Bypass line

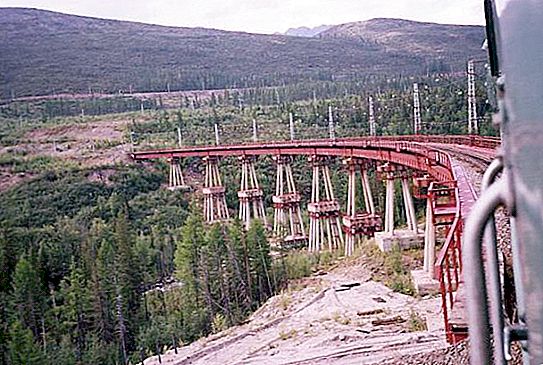

Before the Severomuisk tunnel began to be built, there was already a road going around the ridge. Practice has shown that it is not suitable for operation in the harsh conditions of the work that has begun, so in 1984 it was decided to build a new detour. Today it is no less unique construction than the tunnel itself. Many tourists flock to the ridge in search of opportunities to drive along the road. They are attracted by picturesque views and breathtaking heights, bridges over which you have to go.

The highway winds with serpentines, passes through man-made viaducts and bridges. One of them, called the "Devil's Bridge", laid across the Itykit River, has a sharp turn and, according to eyewitnesses, sways a little at the time of passage of the loaded train. The road is 64 kilometers long; on its way the passenger enters two loop-shaped tunnels laid inside the rocks. The highway is used in parallel with the operation of the tunnel, allowing the movement of some freight trains. More active train passage is planned in case of increased railway traffic along the Baikal-Amur Railway.

The maximum speed does not exceed 20 km / h, the slope in some places is 40%, an additional locomotive is used to advance on steep sections. At present, the bypass road is used for maintenance and repair work trains. Construction was completed in 1989, the road was used for passenger and construction traffic until the Severomuisk tunnel was built. Photos of the bridge and landscapes taken from the windows of the cars following the bypass road are mesmerizing with beauty and give an understanding of the extremity of the building.

Gold buckle

The entire BAM was expecting the start of railway communication in full. The Severomuisk tunnel was almost laid by 1999. Between the teams walking in the tunnel towards each other, only 160 meters remained. Unexpectedly, the rock collapsed, and construction work on the site had to be practically started anew, which took several more months.

The meeting of the crews of drifters, the so-called golden glitch, occurred on March 30, 2001. Two brigades of tunnel builders led by V. Gatsenko and V. Kazeev led the way, the symbolic keys to the tunnel were handed to the Minister of Railways. The connection of the two parts of the tunnel occurred at a depth of 300 meters, the deviation of the axes of the two arms was only 69 mm in the horizontal plane, and the vertical error of the joint was 36 mm. It was the best day for everyone who built the BAM. The Severomuisk tunnel was put into operation only in 2003, it was called the "BAM" gold buckle, which completed a grandiose construction.

Interesting Facts

Twenty-three years of construction turned into victories, discoveries, new technologies. Sometimes it seemed that the project would never be realized, but, despite all the difficulties, the Baikal-Amur Railway brings economic and political benefits to the whole country, the unique Severomuisk tunnel became the final point of connection. The photo of the building surprises with its power, grandeur and causes a feeling of pride.

Construction Facts:

- The total length of the Severomuisk tunnel is more than 15 kilometers, along with the internal development, the length is 45 kilometers.

- During the construction, more than two million tons of soil was processed.

- Used more than 700 thousand cubic meters of concrete.

- More than 70 thousand tons of metal structures were installed.

- In the lining of the tunnel mounted more than 55 thousand cast-iron tubing.

- At different times, 6 teams with a total staff of 8, 000 people worked at the tunnel construction.

- The construction of the tunnel cost the treasury about 9 billion rubles.

- The Severomuisk tunnel at BAM in the tunneling is 67 square meters.

- More than 850 pieces of equipment were used in production processes.

- The tunnel sheathing consists of two, and in the fault locations of three, independent structures, which guarantees safety in the seismically active zone.

- The guaranteed service life is 100 years, experts are convinced that the first overhaul will be required no earlier than 50 years after launch.

- The automated process control system of the Severomuisk tunnel allows real-time monitoring of the microclimate inside the structure, the level of radiation, the movement of trains and other factors of activity.

For many areas of engineering, chemistry, mining and construction, the Severomuisk tunnel became the springboard for inventions. All of the methods known at that time were tested, also completely new approaches were invented, which became the cutting-edge innovation of Russian science. The main problem in the operation of the tunnel is the formation of ice, this process takes place almost all year round and it is necessary to knock down the formed ice manually.

Value

The launch of non-stop traffic along the Baikal-Amur Railway ensured the Severomuisk tunnel. The history of construction has twenty-six years and two eras in the life of the state. The opening of the tunnel reduced the travel time of trains by six times. Now it takes only 25 minutes, and the train traveled bypass for 2.5 hours. The operation of a direct and safe route made it possible to abandon the double locomotive traction, which had to be used on a high mountain route. The safety level has increased significantly: a bypass road looped between hills, where there was always a danger of avalanches.

Cargo traffic along the Baikal-Amur Railway increased by 35%, and growth rates are planned to increase over the next years by an average of 30% per year. It was possible to unload the Trans-Siberian Railway, choking with the flow of traffic. In addition to economic benefits, Russia got a second exit to the Pacific Ocean, the railway infrastructure expanded with reliable and cost-effective directions. To date, the tunnel passes 14-16 freight trains per day.