Today, many countries are undergoing a variety of reforms. All of them are aimed at improving the quality of life, economic growth and so on. However, there is one important factor, which is considered a source that helps to overcome the negative consequences arising from the reforms - the level of labor productivity.

Term designation

It is important here to begin with the fact that labor productivity is, in other words, its fruitfulness. There are two ways to measure it. Either by the amount of consumer value of goods produced in a certain time, or by the amount of time spent creating one unit of goods.

To date, there are two main types of labor productivity - living and aggregate. Productivity of living labor is the amount of time spent on the production of products in a particular area of a particular enterprise. There is also aggregate labor productivity. It is measured in the cost of living and materialized, that is, the past, labor.

It is advisable to increase the level of labor productivity if the share of the living type of employment decreases, but the total volume of materialized labor increases.

And what about each enterprise individually? Here, the level of labor productivity of an employee will be measured by the indicator of output per employee or per unit of time.

Enterprise and Labor

It is worth noting that the level of labor productivity can be determined in another way. This is the ratio of the real volume of production to the number of employees in actual enterprises. There is a certain specificity in such an indicator - it directly reflects the saving of living labor, and also indirectly reflects the saving of social labor.

In order to determine the numerical coefficient of this indicator, you can use the general equation, which looks like this:

Fri = P / T.

In this case, Pt is labor productivity, P is the volume of production in any form, and T is the amount of living labor spent on its production.

Characteristic. Quantity of goods released

The indicators of the level of labor productivity can be characterized by a pair of main parameters. The main indicator is the quantity of goods released over a certain period of time. This indicator is the main, most common and universal among all other characteristics describing performance. It is worth noting here that production can be measured in physical terms, but can in terms of normalized working time. The choice of indicator depends on the units selected for counting all manufactured products.

The complexity of the products

The second indicator of the level of labor productivity, which is the main one, is the complexity of the manufactured products. This ratio will express the amount of time that will be spent on the release of one unit of goods. In addition, it is the opposite indicator. This standard also has several significant advantages:

- helps to establish a direct relationship between the output and labor costs for its manufacture;

- allows you to quite closely interconnect two factors such as measuring performance and determining reserves for its growth;

- will allow you to compare the costs of manufacturing the same product in different shops of the same enterprise.

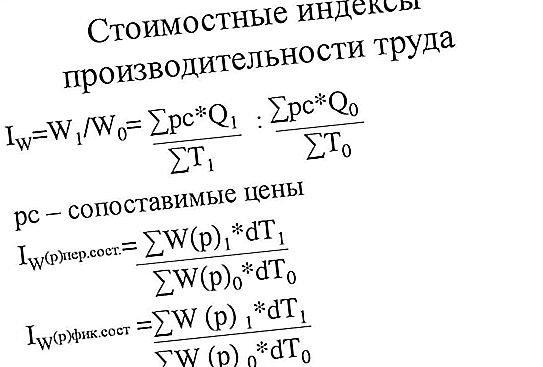

The calculation of the level of labor productivity, namely the calculation of the indicator of production and labor intensity can be represented by the following formulas:

b = W / T, where: B is the total volume of goods released over a certain period of time, B is the cost of goods after manufacture, T is the amount of time spent on the manufacture of one unit of goods.

The second formula looks almost the same:

t = T / V, where: t is the complexity of manufacturing products.

Reserves to improve

Determining the paths for increasing the level of labor productivity is the most important task facing any analytical headquarters of any enterprise. For this reason, in the vastness of domestic business today there is a specific classification of reserves for this increase.

The first option is to increase the technical level. There are several main areas that imply technical advancement. This can be mechanization and automation of production, the possibility of introducing new technological solutions into the workflow, and improving the structural properties of products. This also includes improving both the quality of the finished product and the feedstock for its production. In some cases, the introduction of new energy sources affects the level of labor productivity.

Labor organization and environmental conditions

One of the ways to increase the level of labor is to improve the organization of production and labor itself. In this case, it implies an improvement in both the existing workforce and the recruitment of a new one. In addition, it is possible to improve the norms and service areas, reduce the number of workers who systematically do not comply with the norms. It is very important to prevent such a shortcoming as staff turnover, that is, the constant replacement of workers. To save time, it would be advisable to carry out a complete mechanization of all calculations in the field of accounting and computational work.

Another development option is a change in external, natural conditions. In this case, we are talking about the fact that it is necessary to carry out the process of socialization, to adapt to the needs of the average worker in the enterprise. Most of all, this applies to industries such as oil, gas, coal, ore and peat. To a lesser extent (but nevertheless, this clause also applies to some other sectors) this applies to agriculture and transport.

Other growth opportunities

One of the directions that can help achieve growth in the level of labor productivity is a structural change in production. This includes a partial change in the share of individual varieties of products, the complexity of the production program, the total proportion of all purchased semi-finished products or components for goods, for example.

An important role in the development of labor is played by social infrastructure. If it is not, then it must be created, and the existing one should be developed. This infrastructure should solve financial problems, difficulties arising with the timely payment of wages. The task of this structure will also include many other issues that will be related to meeting the needs of both the enterprise and the work teams working on it.

Average performance

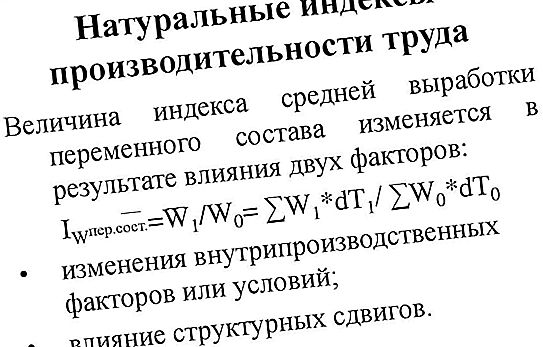

The average level of labor productivity is determined by several parameters. All of them relate to one of two main indicators characterizing labor productivity, which was described above. Here we are talking about the manufacture of goods for a certain amount of time:

- The first of them is the average production of goods in one hour. In this case, in order to determine the average value, it is necessary to divide the number of manufactured products for the selected period of time by the number of man-hours actually worked for the same period of time.

- The dynamics of the level of labor productivity can be determined by the average daily output. As for the calculations, in this case it is also necessary to divide the number of finished products for a certain period of time, but not by the amount of time actually worked, but by the number of actually worked person-days. It is important to add here that the actual hours worked by man-days include both the net time spent on work and the time taken for lunch breaks, breaks for a shift, as well as downtime, if any. In this case, it is clearly seen that the average daily output will greatly depend on the level of hourly output and the length of the employee’s working day.

The last indicator of the level of labor productivity in the enterprise in this case is the average rate of production for one month. It is worth noting immediately that the output for a quarter or a year is calculated in the same way. The calculation of the level of labor productivity for a month, quarter or year is calculated by dividing the output for the selected period by the average payroll number of workers, employees, etc.

Link indicators

These three averages have a definite relationship. So, the average daily output is the product of the average hourly output and the average length of the working day. The average monthly output per worker is the product of the average daily output previously obtained by the average working month of that employee.

This should also include the average output per employee. These are different indicators, since not all workers are workers directly affecting the volume of output. This may include, for example, accounting, maintenance personnel, etc. It can be determined by the product of the average monthly output of one worker and the share of workers in the total number of all personnel.

Performance Level Methods

There are several methods for measuring labor productivity. Their choice depends on which method of calculating products was chosen, that is, on the numerator in the formula. As for the methods, it is natural, labor and value.

In the case of the production of homogeneous products, it is best to choose the method of natural measurement. The labor measurement method is best used if a sufficiently large volume of products is produced at workplaces, teams, etc., with a often changing assortment. If the enterprise produces completely different kinds of goods, then, of course, the cost (value) measurement method is best.

Natural and labor method

In the case of choosing the natural method for measuring labor productivity, all output should be measured in physical quantities corresponding to it, that is, in tons, meters, etc. There is another calculation option, in which you should take the average payroll number of employees, per unit time spent - man-hour, man-day.

It is best to use such in-kind indicators to calculate the productivity of work crews or individually for each employee.

As for the labor method, in this case the output will be determined in standard hours. To get the standard hours, you should multiply the volume of work by the corresponding time standards, and then add the results. However, this method has several disadvantages, which is why it is not able to give an objective assessment of the level and dynamics of labor productivity even for an individual workplace.