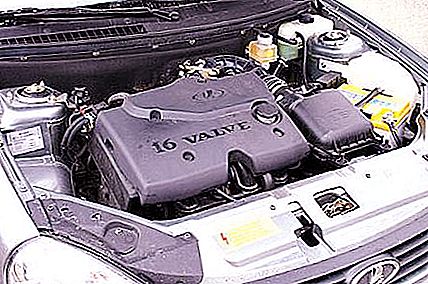

The VAZ-21124 engine is a 16-valve representative of the line of power units manufactured by AvtoVAZ since 2004. In fact, this model was the result of another improvement of the VAZ-2112 engine and was installed on production cars: VAZ-21104, 21114, 21123 Coupe, 21124, 211440-24. Later it was used to create more powerful plants: VAZ-21126 and VAZ-21128 engines of the Super-Auto manufacturing enterprise.

Engine Specifications 21124

In general, the power unit remained quite traditional, that is, four-stroke, with one cylinder row, overhead camshafts and distributed fuel injection (injector).

- Cooling - forced, air-liquid.

- The volume of the cylinders is 1599 cm 3.

- The work of the cylinders is standard - 1-3-4-2.

- Power at 3800 rpm. - 98 l / s.

- The number of valves is 16 (four for each cylinder).

- The diameter of the bottom of the cylinder is 82 mm.

- The piston stroke length is 75.6 mm.

- The compression ratio of the mixture is 10.3.

- The minimum crankshaft rotation speed is 800-850 rpm.

- The recommended brand of gasoline is AI-95.

- Fuel consumption: in the city - 8.9 liters, on the highway - 6.4 liters, in mixed mode - 7.5 liters (distance 100 km).

- The working volume of the oil sump is 3.5 liters.

- Weight - 121 kg.

- The technical resource of the engine 21124 to the first overhaul, declared by the car factory - 150 thousand km (almost a car is able to cover 100 thousand km more).

The cylinder block of the power unit 21124 and its features

First of all, the updated cylinder block differs from its predecessor in its height (the distance between the axis of rotation of the crankshaft and the highest point of the block): for VAZ-2112 it was 194.8 mm, for 21124 it became 197.1 mm. Due to this, the volume of cylinders increased (up to 1.6 cm 3).

To fix the head, the diameters of the holes for the bolts were changed, now their thread should correspond to the dimensions M10 x 1.25.

Another feature of the improved unit is the special nozzles built into the bearings of the main bearings (2, 3, 4 and 5). During engine operation, oil is supplied through them to cool the piston bottoms.

A crankshaft is installed on the engine 21124, the crank of which (R = 37.8 mm) provides an increased piston stroke. The same crankshaft with the marking "11183" cast on its sixth counterweight is mounted on power plants 21126 and 11194.

The pulley for the operation of the gas distribution mechanism is marked "2110-1005030". And the transverse profile of its teeth is a parabolic shape.

The damper through which the alternator is driven by the V-ribbed belt, as well as additional units not provided in the basic configuration, due to the special arrangement of its pulley, torsional vibrations occurring on the shaft are significantly damped. And the drive disk included in the damper design allows a special sensor to read the angle of rotation of the crankshaft.

Drive belts used in the engine and their marking

For the functioning of the timing mechanism in the design of the 16-valve engine 21124, a belt 25.4 mm wide is used, which has 136 parabolic teeth and is marked as “2112-1006040”. The resource before a possible replacement is 45 thousand km.

If no additional mounted units are installed on the motor, namely the power steering pump and air conditioning compressor, then the belt with the marking “2110-3701720 6 PK 742” (working length - 742 mm) is used in the drive of the generator.

If a power steering pump is installed, then a different size belt is installed to drive the generator - 1115 mm. Its marking is “2110-1041020 6 PK 1115”.

The model with a compressor for the air conditioner has an even longer generator belt - 1125 mm, with the marking - "2110-8114096 6 PK 1125".

Features of the piston group

The updated engine also received new pistons, in the bottom of which valve holes are provided: in each piston four grooves are made with a depth of 5.53 mm, which are designed to prevent bending (breakage) of the valves in case of breakage of the timing belt.

Previously, if this happened, the connection of the valves with the crankshaft was lost, their movement ceased, but the shaft itself, carried away by the flywheel, continued to rotate by inertia, and, accordingly, the pistons also moved. As a result, they collided with valves. The result - they bent, broke, or even pierced the bottom of the piston.

The dimensions of the piston rings, which can be both cast iron and steel, remained the same: 82 mm.

The piston pin has a floating fit, and its axial fixation is provided by retaining rings. The length of the finger is 60.5 mm, and its diameter is 22 mm.

The 21124 engine connecting rods are interchangeable with the 2112 model connecting rods.

Cylinder head

The sixteen-valve cylinder head differs from that which was installed on 2112, only with an increased surface area allocated for mounting the intake manifold flanges.

To control the valves, two camshafts are installed in the upper part of the cylinder head: one for the intake group, the other for the exhaust. To distinguish them, the manufacturer puts stamps that are on the neck of the shafts behind the second cam. If the last digit is 14, then the exhaust shaft, if 15, then, respectively, the intake. In addition, the intake camshaft has an untreated metal band next to the first cam.

Since hydropushers are provided in the head, this eliminates the need for the vehicle owner to adjust the thermal clearances between the cams and valves.

However, this convenience forces the driver to carefully monitor the cleanliness and quality of the oil, since the hydraulic pusher mechanism is very sensitive to foreign impurities in the lubricant, the presence of which can lead to failure, and it cannot be repaired, only completely replaced.

The valve stems of the sixteen-valve motor have a diameter of 7 mm, for an eight-valve they are 1 mm larger.

As mentioned above, camshafts rotate thanks to a belt drive coming from the crankshaft. Labels for the correct exposure of the engine operating phases on the pulleys 21124 have a two degree offset relative to the same marks applied to the pulleys of the power unit 2112.

Toothed pulleys of the intake and exhaust shafts differ from each other and are marked by their marking: inlet - "21124-1006019", exhaust - "21124-100606020". In addition, the inlet pulley has a circle near the hub and a shutter on the inside, while the outlet pulley does not.

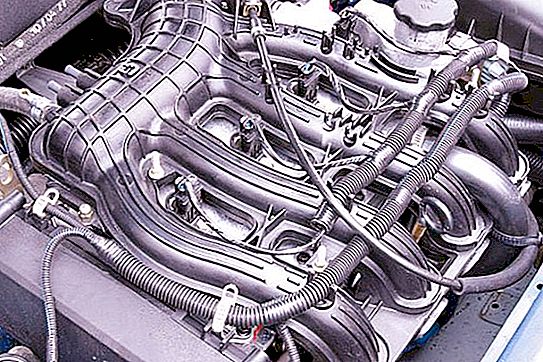

Intake system

The design of the intake system uses a plastic pipe, which simultaneously performs the functions of both the intake manifold and the receiver.

Engine designers used a collector, a unit previously not used in VAZ models and representing a neutralizer, which is integral with the exhaust pipe, as an element of exhaust.

Features of the fuel system and ignition system

First of all, it should be noted that a new type of fuel rail is used on the VAZ-21124, made of stainless alloy and different from the one on the VAZ-2112, primarily because there is no drain line in the fuel system. The necessary pressure of gasoline in the line is maintained by means of a special valve installed in the fuel pump.

As for the ignition system, what is special about it is that high-voltage wires were excluded from its design. The fact is that on the engine 21124 each spark plug received a separate ignition coil.

The coils are fixed directly to the candles and, in addition, have an additional fastening to the cylinder head cover. Thanks to this innovation, the reliability and efficiency of the ignition system has increased significantly.