Grinding metal products is not always done with the help of electric tools. Often, craftsmen use different types of files for such work. Compared to electrical equipment, they are much safer. From the wide variety of tools, the employee has to choose the appropriate material to be processed. It is not difficult to cope with this if you know the intricacies of the work, all types of files and their purpose.

What is a file?

This tool is a product consisting of two parts:

- Steel bar. On its surface, according to special patterns, notches are applied. They may have several options. The most common file notches are rectangular, triangular and round.

- Wooden or plastic handle. Using a clamping ring to prevent it from cracking, it fits onto a tapered shank. Designed for easy operation of the file. If the handle breaks, it is easy to replace. For the production of parts used beech, birch and pressed paper. Its length must be one and a half times longer than the file shank.

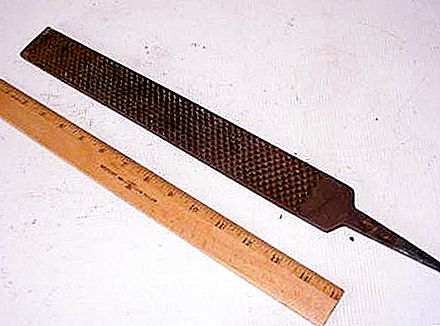

The tool may have different sizes. The standard lengths are 9, 10, 11, 12, 13 and 14 cm. Diameter: 12, 16, 20, 23, 25 and 28 mm.

Operating principle

All kinds of files belong to cutting tools. They are used to create the desired sizes and shapes in the processed products. Files operate by layer-by-layer grinding of surfaces.

Materials

To produce this tool, a very hard, high-quality tool steel is used:

- Marks ШХ15 or 13Х. This is alloyed chrome steel.

- U10A or U13A. These brands are improved unalloyed.

Files are processed by hardening, as a result of which their hardness is 54-58 HRC. These grades are used for the production of files designed for working with metal products. For wood and other materials, tools are taken whose steel is softer.

Single notch tool

This notch (also called simple) is found in special files. The purpose of such a tool is to remove an insignificant layer of metal during filing. Special files are used for processing narrow surfaces. It is convenient for them to sharpen saws on wood. These products are designed to work with soft metals, wood and plastic.

Cross Section Products

Double-notched files are general-purpose tools. On the surface of these products, in addition to the main section, there is an additional one. The main section is intended for removing particles from the workpiece, and the auxiliary section is for grinding them into chips. Files with a double (auxiliary) notch are used when working with hard metals and alloys.

Files for metal. Kinds

GOST 1465-59 - these are the standards that are relied on in the manufacture of locksmith files. Depending on the size of the notches and their number on a 10 mm surface, the following tools are distinguished:

- Bastards. Large notched tools. There are up to 5-12 pieces per 10 mm of file surface. The smaller the number of notches, the larger the teeth. Therefore, a greater removal of particles is performed when filing the product.

- Personal Represented by products with an average notch. The number of teeth is up to 25 pieces.

- Velvet These are the tools with the finest notch. There are 80 teeth per 10 mm of surface.

For convenience, when choosing the necessary tool, the types of files have their own numbers: drastic - No. 1, personal - No. 2, velvet - No. 3-6.

Classification of tools by shape

Machined parts have various shapes. For effective work with such products appropriate types of files are provided. They differ from each other in the shape of the profile (cross section). The following varieties of files are distinguished:

- flat;

- square;

- trihedral;

- round;

- semicircular;

- special;

- knife-shaped or hacksaw;

- rhomboid;

- oval file.

What types of tools are briefly outlined above. What are they for?

Appointment

A flat file is used to work with convex and flat exterior or interior surfaces. Square is used for working with square and rectangular holes and grooves. Such a tool is also called squared. Its length is 35-50 cm. It is effective in cases where it is necessary to remove a metal layer exceeding 1 mm. The trihedral file is used when working with internal corners, grooves, holes and grooves. Round is necessary for filing concave surfaces. Used to work with round and oval holes.

Special files are used for processing corners, inclined and serrated surfaces. This type of tool selects narrow grooves and grooves. Bastard instruments are equipped with the largest teeth and are intended for initial surface treatment, since they allow you to quickly remove a large layer from it (0.05-0.1 mm). At the same time, these files have low accuracy. As a result, the work surface is roughly processed. Personal files are used for finishing filing. In this case, a layer is removed with a thickness of 0.02-0.06 mm. Velvet is used in the final grinding phase. The thinnest layer (0.01-0.03 mm) is removed from the surface of the sawn product. These files have a high accuracy of processing, which is 0.01-0.005 mm.

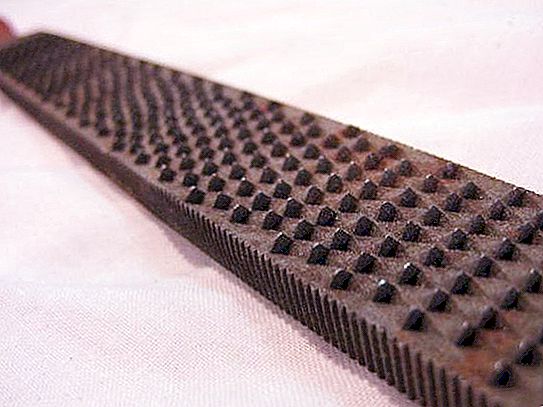

Rasp

In addition to metalwork files, rasps that differ in their notches are used to process metal and other surfaces. Their teeth are large and have the shape of pyramids, behind which there are special grooves. The section on this tool is arranged in rows perpendicular to the axis. Rasps are used in the processing of soft materials: aluminum and duralumin. They are made of steel grades U7A, U10A. Their hardness is 35-40 HRC. Standard tool length: from 25 to 35 cm. Rasps come in four types: blunt flat, pointed flat, round, semicircular. The scope of the tool is medicine and the production of tin products.