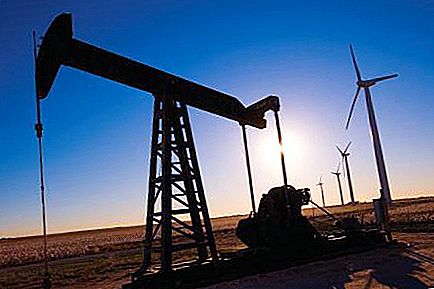

Oil (drilling) towers are structures that are part of drilling stations. They are divided into mast and tower and are used for:

- STR (hoisting operations);

- support (on a tackle basis) of the drill string while drilling;

- placement of drill pipes extracted from the well;

- location of the tackle system;

- placement of STR and ASP mechanisms, platforms: working, emergency evacuation and auxiliary equipment;

- location of the top drive.

Oil rigs in Russia are built mainly at the shipyards of Kaliningrad, Severodvinsk, Vyborg and Astrakhan. All drilling rigs are a complex complex that is designed for drilling any wells, both on land and at sea.

The first oil rigs in Russia were built in the Kuban. And one of them gave an oil fountain, which allowed to produce more than 190 tons per day.

Types of drilling

Drilling is divided into two types: horizontal and well drilling. Horizontal drilling is a trenchless controlled method of laying communications underground using special drilling rigs. Well drilling is the process of mining large and small diameters. The bottom is called the bottom, and the surface - the mouth.

Drill string

The drill string is the main part of the construction of the oil rig. The column consists of:

- upper and lower lead pipe sub;

- lead pipe;

- lead pipe safety sub;

- lock couplings;

- lock nipple;

- drill pipe;

- tread;

- UBT sub;

- directly to the UBT;

- centralizer;

- overhead shock absorber.

The drill string itself is an assembly of special drill pipes that are lowered into the well. Pipes are designed to supply mechanical and hydraulic energy directly to the bit, in order to create the necessary load on it and control the well trajectory.

Drill Tower Features

The oil rig performs the following functions:

- transmits rotation between the rotor and the bit;

- perceives jet moments from face motors;

- feeds the flushing agent to the face;

- brings power (hydraulic) to the engine and bit;

- presses a bit into the rocks using gravity;

- provides replacement of the engine and chisels by transporting them to the bottom;

- allows for special and emergency work in the well itself.

Oil rig work

The oil rig is designed for lowering and raising the drill string into the well. At the same time, the tower allows you to maintain it on weight. Since the mass of such supporting elements is multi-ton, special equipment is used to reduce the load. And lifting equipment is one of the main components of any oil rig.

The oil rig also performs a number of other works: it places the hoist system, drill pipes and other equipment in the drill string. When the tower is operating, the greatest danger is their complete or partial destruction. Most often, the main reason is insufficient supervision of the structure during operation.

Drill bits are lowered and raised several times. These operations are strictly systematic and consistent. Winch loads are cyclical. When the ascent occurs, the power of the hook goes from the engine to the winch, during the descent - vice versa. In order to maximize the power used, multi-speed operation modes are used. During and after drilling, candles rise strictly at the 1st speed.

Varieties of Drill Rigs

Oil rigs are divided into different types in height, design and load capacity. In addition to mast-type towers, tower towers are also used, assembled from top to bottom. Before starting assembly, a lift is mounted on the base of the tower. After complete installation, it is dismantled.

Tower structures

When installing an oil derrick, the construction of near-by-tower facilities, such as:

- gearbox;

- pumping shed;

- receiving bridge (inclined or horizontal);

- rock cleaning system;

- warehouses for bulk materials and chemicals;

- auxiliary facilities during drilling (transformer sites, etc.);

- household objects (dining room, dormitories, etc.);

- tackle system;

- Winches

- tools for unscrewing and screwing up BT.

Offshore oil rigs

From a drilling tower, which is located on land, the sea is distinguished by the presence of water between the rig and the wellhead. There are several ways of drilling in water areas:

- from stationary offshore platforms;

- from gravitational offshore platforms;

- from drilling rigs;

- from semi-submersible drilling rigs;

- from drilling ships.

An oil rig at sea is a platform whose base rests on the bottom, and it itself rises above the sea. After the end of operation, the platform remains in place. Therefore, a water separating platform is provided that isolates the well from the water and connects the mouth to the platform platform. Wellhead equipment is mounted on the SME.

In order to tow the platform to the well, five tugboats are used, and auxiliary vessels (escorts, tractors, etc.) also take part. A marine gravity platform is a foundation made of steel and reinforced concrete. An oil rig is being built in deep bays and delivered by tugboats to the desired point. It is intended both for drilling and for storage and production of oil until it is dispatched. It has a large weight, therefore, additional devices to hold it in place are not required.

Self-elevating installation has good buoyancy. It is installed on the bottom with the help of lifting mechanisms to a height unattainable for waves. After operation, casing and liquidation bridges are used.

A semi-submerged installation consists of an equipped platform and pontoons connected by columns. Pontoons are filled with water and immerse the platform to the desired depth.

Self-elevating units have good buoyancy and a large hull that provides towing immediately with equipment installed on them. At the set point, they are lowered to the bottom and immersed in the ground.