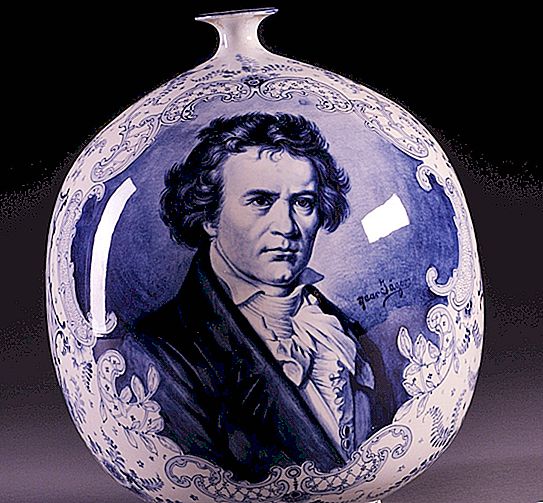

Delft porcelain is a ceramic made in blue and white, which is produced in the Dutch city of Delft. Products from such porcelain have long become an urban symbol and a very popular souvenir among tourists. Production technology, appearance history and interesting facts will be discussed in this article.

Appearance story

The origin of Delft porcelain dates back to the 17th century, when pottery in a Dutch city called Delft lived through its golden age. One of the main roles in the development of porcelain production was played by the rise in maritime trade. At that time, one of the six representative offices of the East India Company worked in the city, and its ships brought samples of blue-white and polychrome ceramic products from the Far East to Holland.

During this period, potters from Delft experienced an acute shortage of clay, so it was brought from other countries. Until 1640, only ten potters could join the Guild of St. Luke (workshop association of sculptors, artists and printers), which gave them great advantages.

The increase in ceramic production was due to the fact that the quality of river water was extremely low. Because of this, the vast majority of breweries closed, and pottery workshops were opened in their place. Also, a large number of breweries closed after a strong explosion of powder depots, which occurred in 1654. A vast part of the city was almost completely destroyed.

Demand growth

The need for Delft porcelain was also due to the fact that all goods were delivered to Holland by sea, which was associated with great risk. Delivery of ceramics from China was very problematic, quite often ships did not sail to Holland. As, for example, a Swedish sailing ship in 1745, which flew onto a rock under water and sank 900 meters from the harbor with a large batch of china from China. These events also increased demand for the products of craftsmen from Delft.

One of the technological features of Delft porcelain was the use of a multiple-cycle glazing of manufactured products. It was carried out with lead glaze, and the final firing was carried out at low temperature, which made the product similar in characteristics to faience.

Heyday of production

Porcelain production in Delft flourished from the mid-17th to the second half of the 18th century. Delft porcelain was not very durable, mainly tiles were made, which were faced with stoves and walls, as well as tableware and decorative dishes. Initially, the masters copied the shape of the dishes and its painting from Chinese designs (the ornaments and landscapes of China were in demand). In the future, potters began to produce items with scenes from the Bible and landscapes that are inherent in the vastness of Holland itself (windmills, flower arrangements, fishing boats and the coast).

The pattern on the manufactured products was distinguished by beauty and quality of workmanship; the graceful drawing of thin lines distinguished this porcelain from any other. Since 1650, local masters, in addition to the brand name, put their own brand name. On Delft porcelain, the mark guaranteed the high quality of the product.

Sunset popularity

Problems with the sale of porcelain products by Delft craftsmen began in 1746, when an English chemist, Sir William Cookeworthy, invented a recipe for white clay. Dishes and products made of new material were more durable. The manufactured products were covered with transparent glaze, which gave the pattern depth, volume, brightness and clarity.

English ceramics were inferior to the Delft faience in decoration. The British had a drawing that was not very neat, and the faience itself was rough and hard, the glazed coating easily cracked and chipped. However, English ceramics, although different from Delft porcelain, were beautiful in their own way. But its main advantage was its low price, since it was painted not by hand, but by printing.

Dutch manufacturers could not compete with the British, and potters from Delft began to close their workshops. At the end of the 19th century, only one workshop remained from the flourishing porcelain production. Its owner preserved it due to the fact that he abandoned the traditional hand-painted products and began to apply patterns in print.

Production technology

At the very beginning of the production of Delft porcelain, gypsum forms are taken and filled with a clay solution. Gypsum absorbs excess moisture very quickly, and after solidification in the form, a blank of the future plate, mug or vase is formed. Using a knife, sponge and water, the master separates the remaining seams from the workpiece. Then the future ceramic product is sent to the furnace for 24 hours for the first firing, withstanding a temperature of 1160 ° C.

After that, the product, which is called a biscuit, is sent to the artist who paints it. This is the most painstaking and responsible part of the production of Delft porcelain. All products are painted by the master manually, it is easy to notice, because on the ceramics there are traces of the brush.

Painting and completion of the process

The paint is immediately absorbed into the porous texture of the clay, so it is not even possible to fix an insignificant blot. If, however, the artist made a slightly sloppy pattern, the product immediately loses value.

After the product is painted, the pattern depicted on it first looks voluminous and dull. And only after glazing and secondary firing at a temperature of about 1170 ° C is the process considered complete. Glaze not only creates a protective layer on porcelain, but also gives the painting visual depth and volume. In the photo of Delft porcelain, you can see what bright and voluminous drawings are obtained after the completion of the production process.

Preserving Traditions

The secret to the manufacture of this porcelain could be irretrievably lost if in 1876 two Dutch entrepreneurs did not acquire a factory to preserve and resume the old production of Delft ceramics.

In 1884, they created a new recipe for white clay, which is superior in strength to English products. Then they completely changed the technological process and began to produce ceramics. Immediately after this, the products began to enjoy success, in Amsterdam, Delft porcelain was bought up by numerous tourists. This contributed to the growth of recognition of Dutch ceramics throughout the world.

In 1919, the Delft brand was awarded the royal title for preserving and reviving the pottery traditions of Holland.