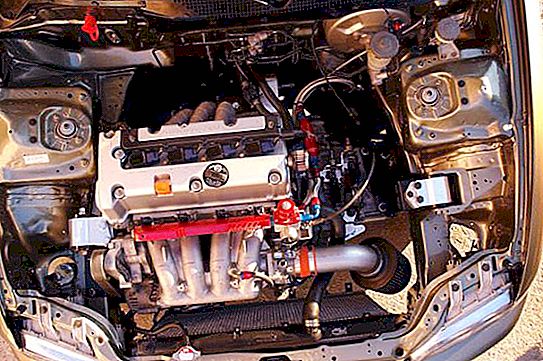

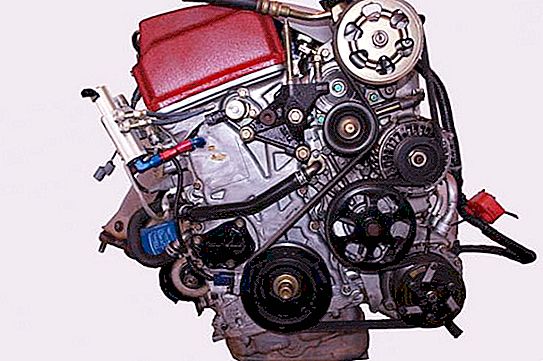

The K20A engine is a modern four-cylinder two-liter in-line gasoline engine manufactured by Honda Motor Co. Ltd. This type of motor is installed in many modern models of Honda cars. At the moment, this engine is the most high-performance and perfect serial "heart" of the Honda brand.

K20A engine: technical specifications

As already announced, the unit is installed in cars with front-wheel drive. The compression ratio of this engine family varies from model to model. Volume - 2.0 liters, the number of valves - 16. Power depends on the car, designed to install the engine. The "strangled" version develops 150 liters. with., while the analogue for an active and confident ride - 220 liters. with. The maximum torque remains virtually unchanged and ranges from 179 Nm to 206 Nm.

The declared maximum is achieved at different speeds: from 4000 rpm to 7000 rpm. 8500 rpm limited by electronics are the maximum revolutions at which the two-liter K20A engine is capable of working. Technical characteristics of this unit are considered the most advanced among competitors.

Location

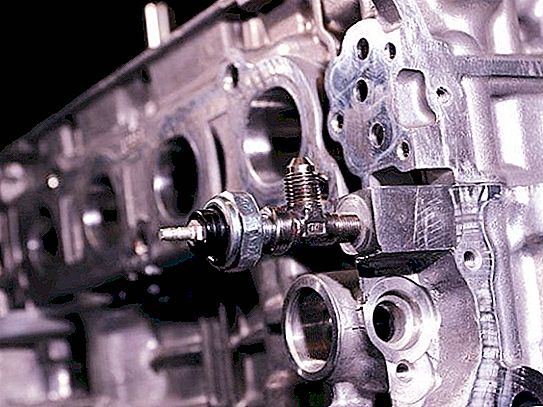

“Where is the K20A engine number?”, - many motorists ask this question. The fact is that finding this number is not so simple. You must have some knowledge. For example, in order to understand where the K20A engine number is located, you need to pay attention to the hole in the radiator grille, behind which the hood lock is located.

After that, with the help of a flashlight, you should illuminate that part of the engine that is between the cylinder head and the radiator grill, and look through the hole in the grill at about an angle of 45 degrees. If you could not see the engine number you are looking for, you should contact the official service center with the appropriate question.

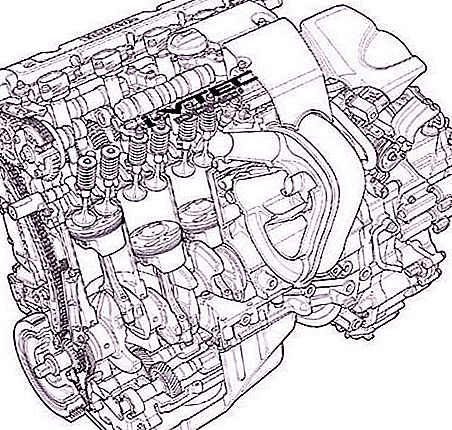

K20A engine: device

The arrangement of the engine in relation to the car body is transverse, a four-cylinder in-line layout is used. The cylinders are numbered so that the first one is located at the crankshaft pulley. Camshafts, by the way, there are two of them, are located on top. Liquid cooling is used.

All engines of the K20A series are equipped with a variable valve timing system VTC and valve lift VTEC. The VTEC system, in turn, can be implemented for both shafts, and only for the intake. This parameter is the main difference between K20A and K20A6 engines.

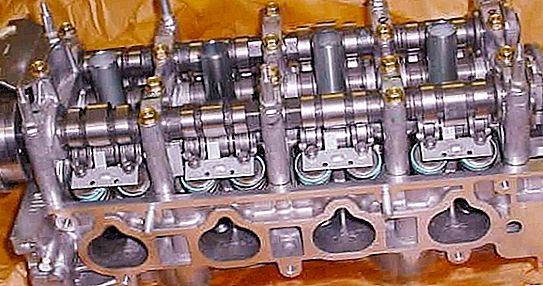

Cylinder block and cylinder head

The cylinder block is cast from aluminum alloy using GDC technology. In order to increase the stiffness of the main block, the main bearings are closed with a lower one-piece cover, which is attached to the block with 24 bolts. For cooling, special channels are used in the cylinder block through which cooling liquid flows. In order to lubricate the pistons, crankshaft and connecting rods, as well as to supply oil to the oil nozzles, a whole system of special horizontal channels is used. The front of the unit is equipped with a vertical channel in order to be able to supply oil to the cylinder head.

The cylinder head is cast from an aluminum alloy. The gas distribution mechanism is based on two camshafts (DOHC). The camshafts are driven by a chain connected to the crankshaft. In the cylinder head there is also a bed for camshafts. The rocker arms that are part of the VTEC system are installed in it. The engine uses new modern materials, which has reduced the weight of the springs and the likelihood that resonant oscillations occur.

Crankshaft and camshafts

The crankshaft is made of steel and is five-bearing. Provided that the block of balancing shafts is used, eight counterweights are installed on the crankshaft. If the block of balancing shafts is absent, then only four counterweights are used. Oil is supplied to the crankshaft using a special channel, which is held from the side of the main cylinder block. On the toe of the crankshaft of the engine are the gears of the gas distribution mechanism drive and the oil pump drive.

Each camshaft performs its function: one of them drives the intake valves, the other - exhaust valves. The valves of the K20A engine and the clearance in their drive are adjusted using special adjusting screws. Each camshaft has five support journals. In order to lubricate the cams and necks with the help of engine oil, it first enters the rocker arm for the VTEC system, then to the special oil channels that are located on the camshaft in the second supporting journal. The valve timing on the intake valves is automatic and is carried out using the VTC system.

Timing chain and timing chain tensioner

The gas distribution mechanism in this type of engine is driven by a chain transmission. There is a special tensioner that works due to oil pressure and automatically adjusts the tension of the timing chain. To eliminate unnecessary vibrations of the chain, there are special herbal dampers, which are installed on top and side. In order to reduce the amount of noise during operation of the timing chain, the pitch of the drive chain is reduced.

Cooling and lubrication system

The K20A engine is equipped with a closed-type liquid cooling system. Coolant circulation is forced. The belt used to drive the mounted units also drives the coolant pump. The thermostat with a bypass valve, designed to maintain the optimum temperature of the cooling system, is located in the inlet pipe for the coolant. This device determines in which circle, small or large, to let the cooling fluid through the radiator.

The oil used to lubricate the engine undergoes full-flow cleaning and is supplied under pressure to the main moving parts and components of the engine. A trochoid type oil pump is used. Inside such a pump there are two rotors - master and follower, their gearing is internal. And they rotate in the same direction. The pump is driven by a chain from the crankshaft. The oil filter is horizontal at the bottom. An oil cooler located between the oil filter and the cylinder block serves to reduce the temperature of the oil that is supplied to the engine lubrication system.

Fuel injection into the K20A engine: device and characteristic

The fuel injection system used in this engine is the PGM - FI (or PGI - Programmed Fuel Injection) system, which allows sequential multi-point injection.

The installed fuel pressure regulator makes it possible to control the pressure at which fuel is supplied through a special filter to all nozzles through a pump. In order to simplify the fuel system, save space and increase the reliability of the fuel injection system and its operation, fine and coarse fuel filters, a sensor used to indicate the fuel level, as well as a fuel pressure regulator are located in the fuel pump housing.

Based on the readings of various sensors, the control unit controls the amount of mixture that is needed for injection, the composition of this mixture and the ignition timing. In accordance with the readings of the oxygen sensor and the mixture composition sensor, which is installed in front of the catalyst in the exhaust system, the control unit can specify various compositions of the fuel-air mixture. In addition, he calculates the amount of fuel supplied to the K20A engine per cycle of operation, and does this in the following sequence:

- A decision is made on whether to inject fuel.

- The determination of the mode in which the vehicle is moving begins. For this mode, the position in which the accelerator pedal is located is calculated. The speed of the car and the frequency with which the crankshaft rotates are also determined by reading the sensor signals.

- A preliminary calculation of the amount of injected fuel begins, based on how often the crankshaft rotates and on the readings from the absolute air pressure sensor in the intake manifold. At the same time, better fuel economy parameters are achieved when driving in different modes.

- The control unit re-reads the signals that the sensors supply: the position of the throttle valve, intake air temperature, coolant temperature, atmospheric pressure device, oxygen level, mixture composition, battery voltage, opening of the electro-pneumatic valve in the recirculation system. Based on these readings, corrections are made to the pre-calculated amount of fuel.

- The final action - the control system gives a signal about how much fuel must be supplied to the system.

In order to increase efficiency, make sure that the fuel is completely burned out and for better atomization, special nozzles are used, in which there are 8–9 openings.

The control unit reads information from the camshaft and crankshaft position sensors in order to determine which of the cylinders it is necessary to supply the mixture at the moment, as well as the moment of injection.

The control unit is equipped with an overload protection function. This allows you to automatically stop fuel injection if the crankshaft rotates at a frequency that exceeds the maximum permissible. As a result of such manipulations, the engine speed drops.

Diagnostics

It is worth noting the diagnostic system that the K20A engine is equipped with. Characteristics and work process consists of the following items:

- The electronic control unit (ECU) is equipped with a built-in self-diagnosis system that continuously monitors the condition of the engine according to the signals of various sensors. In the event of a malfunction, the system identifies it and notifies the driver of this by activating the Check Engine indicator on the instrument panel. In this case, the corresponding diagnostic code of the ISO 15031-6 standard and manufacturer codes are written directly to the computer memory.

- In order to read diagnostic codes, you need to connect a special scanner to the DLC connector. There is the ability to delete codes and read Freeze Frame data using a scanner. The diagnostic connector is made in accordance with the SAE standard, and pin No. 7 is made in accordance with the international ISO standard. This conclusion has support for the exchange of information on K-LINE.

- When recording most of the codes, an algorithm consisting of two stages is used. It is used in such a way that at the first manifestation of a malfunction, its code is temporarily recorded in the computer memory. If this malfunction occurs repeatedly during the next duty cycle, then in this case the Check Engine indicator is activated. Driving test No. 2 is carried out in the same way and with the same driving mode, but a prerequisite is that the ignition must be turned off between cycles.

- If any malfunction occurs, the conditions under which it occurred are recorded in the memory of the ECU (Freeze Frame).

Air intake systems and additional air supply

The intake manifold mounted on the K20A engine is located in front, between the radiator and the cylinder head. The outlet is, on the contrary, behind, next to the location of the partition of the engine compartment.

Additional air to the nozzles is supplied using a separate system. The fuel injected into the engine goes through the stage of mixing with the supplied air, which helps the fuel to evaporate better and prepare a more efficient fuel-air mixture. With this, a more uniform combustion process can be achieved, even if the mixture is lean. The result of these actions is to reduce the amount of hydrocarbons in the exhaust gas and facilitate starting an unheated engine. A special valve is installed in the pipe of the cooling system, which regulates the air supply. The level of its opening is regulated depending on the change in the volume of paraffin, which, in turn, depends on the temperature of the liquid used for cooling.

Intake and exhaust manifolds, exhaust system

The intake manifold is made of aluminum alloy and can be equipped with a geometry change system. The exhaust manifold is made of steel, which serves to reduce its weight.

In sports versions of Honda cars, there is a special valve installed inside the muffler. It is used to reduce the inverse resistance of the exhaust gas. The valve opens with pressure, which occurs at high speeds of rotation of the crankshaft. In this case, the exhaust gases exit the muffler without any resistance.

Oil selection

Probably, every car owner is interested in the issue of changing the oil. What kind of oil to pour? The K20A engine most favorably "responds" to the native lubricant.

Since engines of the K family are high-speed, it is worth noting that the range of oils suitable for use is minimized. In general, like any manufacturer, Honda recommends pouring oil of its own production. The characteristic of the oil to be filled depends on the temperature spectrum at which the vehicle is operated. But if it is not possible to fill the factory oil, then some car owners recommend the products of Mitasu or Zeppro Idemitsu as a good alternative.

If suddenly there was a knock on the pallet of the K20A engine, there is no reason to hesitate to contact a service center or the nearest competent service station. Most often, the problem is directly in the wrong choice of oil, as well as in improper operating conditions of the engine.