Industrial production of bearings, stamped and cutting tools is carried out using various grades of steel. Among them, a special place is occupied by X12MF steel.

The characteristics of this brand are also appreciated by many companies engaged in the production of exclusively knife products. Today this material is very popular both among manufacturers and among buyers of various cutlery.

Brand class

In the engineering industry, X12MF steel is considered the main brand. The characteristics of the material differ from the rest of the carbon tool brands in their high structural density. This type of steel belongs to the class of stamped tools. For a long time, it was used only in the manufacture of dies for bending and molding products. Since forged steel X12MF is highly resistant to external physical influences, it is used in heavy industry and engineering industry.

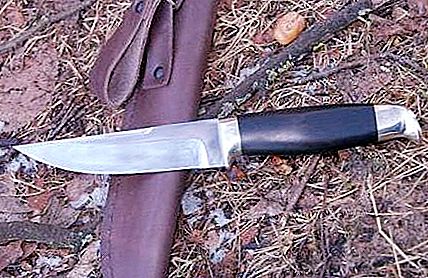

This steel is a high-quality material from which hunting knives are made. As evidenced by numerous consumer reviews, such cutting products are very durable and do not stupid for a long time, which is important for the hunter. The advantages of the material are taken into account by manufacturers using X12MF steel in the production process.

The properties

The advantages of this steel grade include:

- high strength;

- heat resistance;

- hardenability;

- hardenability;

- wear resistance;

- manufacturability.

The latter property is appreciated by the craftsmen processing steel X12MF. The characteristics of the brand allow it to be processed using cutting, pressure and grinding procedures.

Products

The brand X12MF is used in the manufacture of:

- profiling rollers having a complex shape;

- complex hole-piercing matrices with which sheet metal is formed;

- reference gears;

- rolling dies;

- wolves;

- matrices;

- punches.

What provides density?

The high performance possessed by X12MF steel, the characteristics of this brand are achieved by forging blanks. During the procedure, a round steel bar taken for processing is placed in a special furnace. There it is heated to a certain temperature. After that, a bar from X12MF is machined mechanically with a hammer. The result should be a strip of steel with a very high density. Then it is again placed in the hearth and subjected to heat treatment. After the strip has warmed enough, it is chopped into several small blanks.

In the future, by processing they are given the desired wedge-shaped form. In this way, knives are made of steel X12MF. Owner reviews of such blades are mostly positive: the steel structure of the workpieces during their processing with a hammer becomes very dense, and this, in turn, provides the blades with high resistance to dullness.

Why are alloying elements needed?

In its original form, any steel is an ordinary alloy, which includes iron and carbon. Depending on the task that the product will perform, a chemical change of the alloy is carried out, and this, in turn, will improve and adapt the X12MF steel. Characteristics (reviews confirm the information) of the improved material are in the following list:

- high strength;

- increased corrosion resistance;

- durability of operation;

- high cutting ability.

X12MF acquires quality data as a result of the addition of alloying elements to it. The procedure is carried out in a certain temperature mode in compliance with the required number of hardenings.

Structure

Knife steel X12MF consists of the following chemical elements:

- Chromium. It is introduced to improve the cutting properties and wear resistance of this steel grade.

- Tungsten. This chemical element increases hardenability.

- Vanadium. It is necessary so that particles of the excess phase are qualitatively distributed in the steel structure. Due to the presence of vanadium in the composition, sensitivity to overheating is significantly reduced. With an excessive amount of substance (over 5%), the plastic properties that X12MF steel should have are reduced. Characteristics (reviews of owners of steel products fully confirm this) of this material depend on the amount of vanadium. The lower the presence of this chemical element, the higher the strength and ductility indicators of steel.

- Molybdenum. This chemical element increases the viscosity and hardenability of steel. At the same time, the presence of a large amount of molybdenum can reduce the resistance of the alloy to scale formation. It is desirable that the content of this substance in X12MF does not exceed 1.7%.

- Manganese. This chemical element is necessary to reduce warpage during hardening of products.

- Silicon. Used to increase resistance to tempering during heat treatment.

The manufacture of alloy stamped steel is carried out taking into account the requirements of GOST.

X12MF: abbreviation

Deciphering steel grades is not difficult. First of all, you need to know what letters are used to designate chemical elements. For the designation of chromium, the letter X is used, nickel - H, cobalt - K, vanadium - F, molybdenum - M, titanium - T, copper - D, etc. Therefore, X12MF steel contains chromium, molybdenum and vanadium. The number indicates the content of the main alloying element. It is chrome. 12% of this chemical element contains X12MF steel.

Characteristics

Knives created from the material of this brand have the qualities that give the steel the components contained in it. Since X12MF is carbon steel, its products are characterized by high wear resistance. This means that a blade with a high carbon index can be used for a long time without additional sharpening. The content of 16% of carbon determines what characteristics the X12MF steel will have. Knives made of chromium-containing steel (12%) almost do not rust. In the event that the steel contains 14% chromium, it becomes completely stainless. The presence of these chemical elements provides blades from X12MF strength and durability. Providing abrasion resistance is possible due to an additional alloying additive. For this purpose, molybdenum is added during annealing in X12MF. As a result, the steel is calcined evenly. A knife made from it is a product with uniform sharpening. As evidenced by the numerous reviews of the owners of such blades, in the structure of knives there are no weaknesses.

Testing knives from X12MF

Testing steel hunting knives consists in the following actions:

- With a knife, cuts are made on a rope 200 mm thick. According to the reviews of the owners, a blade can calmly make at least three hundred rifling. Only then will it be noticeable that the blade has become dull.

- For rifling, oak bars are also used. With this material, a knife can make no more than a hundred rifling.

- The newspaper is cut. The essence of this test is also to check the sharpness of the knife. To do this, one newspaper sheet is gently lowered onto the blade. Usually the leaf is easily cut into two parts solely under the influence of its weight.

Despite all the advantages of steel grade X12MF, many owners of such blades recommend that you adhere to two rules:

- Since hunting knives are not throwing weapons, it is undesirable to throw blades into trees or other surfaces.

- Never check knives for bending or stepping on them.

For those who have acquired one of these knives, experienced hunters recommend that you do not waste your energy polishing the blade. According to many consumers, X12MF is very poorly polished. Consequently, a knife made of steel of this brand will never shine brightly.

The characteristic color for his blade is matte. In this regard, knives made of steel X12MF are often confused with damask.