Relay - a device for turning on and off electrical circuits, one of the "long-livers" among the radio elements. Despite the relatively simple design, it is highly efficient and reliable. Even currently, on some devices there is no alternative. Despite the existence of power semiconductor devices, relay contacts are still the easiest way to switch powerful loads in low-current circuits.

Appointment

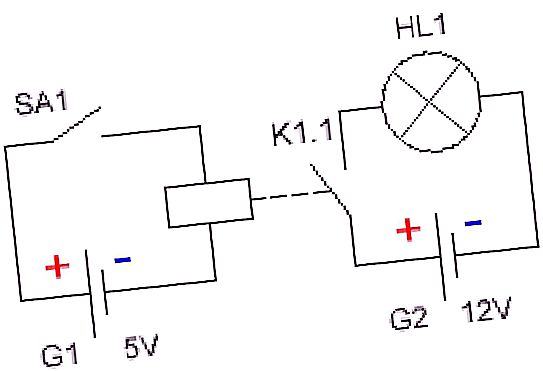

An elementary electrical circuit consists of a power source, a circuit breaker and a load. Ideally, all three elements should correspond to each other in voltage, and most importantly - in current. This is a prerequisite for the normal operation of the circuit. If the permissible current through the switch is greater than the current consumed by the load, nothing bad will happen. Moreover, such a breaker will last much longer. When the current flowing through the switch exceeds the maximum permissible, problems begin.

They are expressed in the sparking of contacts, which ultimately affects the duration of their service. It would seem that it is enough to install a switch corresponding to the load and everything will be fine. It is, but not always possible. The fact is that the higher the permissible current, the larger the dimensions of the circuit breaker. In this case, the load can be quite large, but it must be controlled, for example, from a remote control on which there is no place for a large switch.

In this case, and set the relay. Its inclusion requires a relatively small current. The load power can be very significant, while the relay can be moved outside the same control panel and installed in a place where the dimensions do not matter.

Relay device

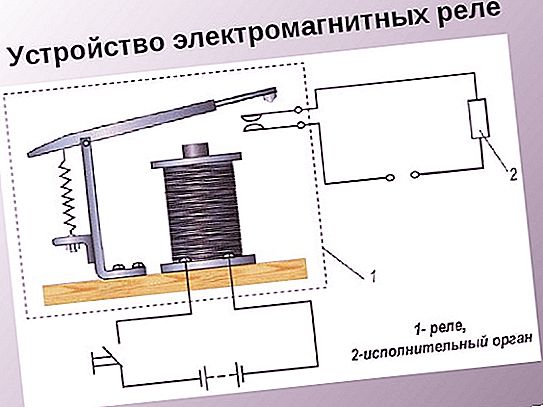

It should be noted immediately that there is a wide variety of voltage control devices. The article will consider the most common electromagnetic relay. It consists of the following parts:

- core electromagnetic coil;

- anchor;

- switched relay contacts;

- return spring.

The relay is made in a closed, sometimes sealed enclosure. This protects its mechanism from dust and moisture. To connect the device to the outside of the housing, there are pin leads and coil windings.

Principle of operation

The key element of the relay is an electromagnetic coil, in this case it is called a winding. In design, it performs the function of a solenoid. When current flows through the coil, a magnetic field arises, due to which an armature is fixed to the core, which is rigidly connected to the moving relay contact. When moving, it closes the electric circuit. After the voltage is removed from the winding, the armature under the action of the spring returns to its original position, opening the relay contacts.

The resistance of the coil, and hence the number of turns, depend mainly on the power of the connected load. In accordance with this, the dimensions of the winding and relay also grow. However, in any case, the current consumed by the coil is tens, or even hundreds of times less than that switched by the contacts. This property allows you to use the relay as an intermediate. First, the relay itself is powered by a low-current switch, and then it supplies voltage to the consumer with its contacts. This use of the device has become the main and most widespread. In this case, experts say that the load is connected through the contacts of the intermediate relay. Thus, the dependence of the switch on the power of the powered device is eliminated.

What are contacts

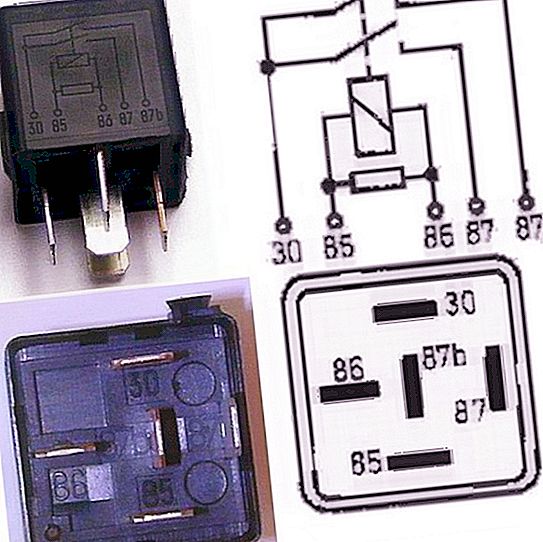

In relation to the relay, this is not an idle question, as it may seem. The fact is that in this case it is not only mechanical contacts that are switched inside the device. When people talk about a relay, they mean all the conclusions that are on its case. You can divide them into two types:

- Winding contacts. Sometimes there can be more than two of them on the relay.

- Switched.

To avoid confusion, these pins are often called relay connection pins. Sometimes their number can reach 10. However, due to the lack of standardization, it is not always clear where to connect which circuit. The pinout of relay contacts, which is almost always applied to its body, will help you figure it out. If not, you have to look for a description. The contacts of the winding are connected directly to its terminals. They are supplied with voltage, from which the relay is activated. There can be several windings and each will have its own pair of contacts. Sometimes coils can be interconnected by conductors, if it is necessary to provide a certain algorithm for their operation.

Switched Contact Material

The service life of some relays is tens of years. At the same time, all its parts experience heavy loads, especially contacts. Firstly, they experience mechanical stresses associated with the movement of the anchor. Secondly, they are negatively affected by large load currents. Therefore, the relay contacts must meet the following requirements:

- High conductivity. Provides low voltage drop.

- Good anti-corrosion properties.

- High melting point.

- Small erosion. The contacts must be resistant to metal transfer, which is inevitable with constant closure and opening.

All of these qualities directly depend on the material used. Consider the main metals used to make the relay:

- Copper fully meets the requirements put forward, with the exception of resistance to corrosion. Therefore, it is often used in relay contacts with a sealed enclosure. In addition, copper has another plus - a relatively low cost compared to other metals. Its only drawback is the tendency to oxidize during prolonged use. Therefore, it is used where a short-term mode of operation is provided, for example, in the contacts of the cornering relays.

- Silver has excellent conductivity and wear resistance. It does not cause sparking when switching inductive loads. At the same time, silver contacts do not have sufficient arc resistance, and therefore cannot be used to control loads of significant power. In addition, they have a fairly high cost. Therefore, the contacts have a combined design - copper with silver plating.

- Tungsten has great durability and resistance to high temperature. The contacts made from it are capable of switching very high currents (tens of amperes).

In addition to the material, the relay contacts differ in the way of switching.

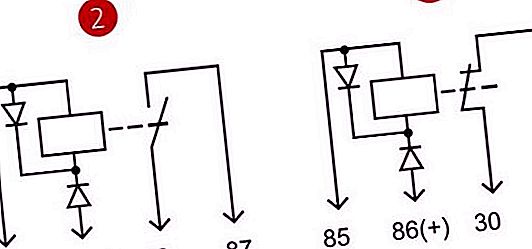

Normally open

It is these contacts that have been considered so far. In the neutral position, i.e. when no power is supplied to the relay coil, they are open. After turning on the voltage, the armature is attracted to the core and the contacts close. Normally open contacts are most often used in various electrical circuits, mainly as intermediate contacts.

Normally closed

The algorithm of their work is exactly the opposite. The contacts are closed when the relay is de-energized, and are disconnected when voltage appears on the winding. This is used in the implementation of various interlocks and in signaling circuits. A typical example of using normally closed contacts is a mechanical relay regulator. We will briefly talk about his work below.

Through normally closed contacts, voltage is supplied to the field winding. Accordingly, when the anchor is released, the generator generates an electric current. The battery is being recharged. As soon as the voltage in the on-board network exceeds the set value, the armature is attracted, the contacts of the relay-regulator are released, the field winding is de-energized. As a result, the voltage at the output of the generator decreases.

By the way, despite the fact that electronic relay controllers have long appeared, owners of old cars are in no hurry to put them instead of mechanical ones. This is due to the trouble-free operation of the latter for many years. This is the question of reliability.

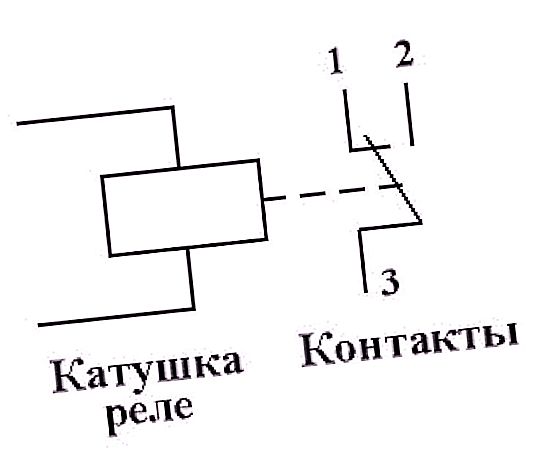

Switching

In this case, the relay has both normally closed and open contacts. And all of them are not four, as it may seem, but three. The fact is that one of them is common. In total, there are 5 contacts on the relay case (two winding leads and three switched ones). Due to its versatility, radio-technical elements of this type are most widely used. Therefore, most modern relays have switching contacts, sometimes even several groups.