With the invention of various tools that work from the network, the work of professional masters and amateurs has become much easier. The result is more consistent with modern requirements.

A hand-held circular saw with the possibility of stationary installation is indispensable for people whose activities are related to woodworking. Today, there are many manufacturers offering the consumer a similar technique. Choose the best option will help expert advice.

General information

The appearance of a circular saw in the twentieth century significantly improved such a labor-intensive type of activity as woodworking. Since then, this device has been supplemented by various elements and improved.

The first company that managed to create a truly affordable circular for the consumer was the German company AEG.

A hand-held circular saw with the possibility of stationary installation is a high-class tool. It owes its ability to work from a household network (220 V) to that first German-made technique.

The process of supplementing the device with various functions and innovations is almost complete. Nowadays, manufacturers of electric tools only increase the quality of their products, the safety of their operation, as well as the accuracy of settings. To these parameters today advanced requirements are put forward.

Scope of application

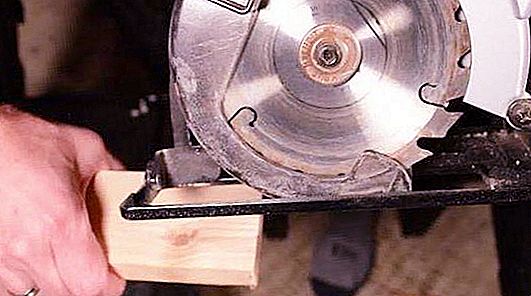

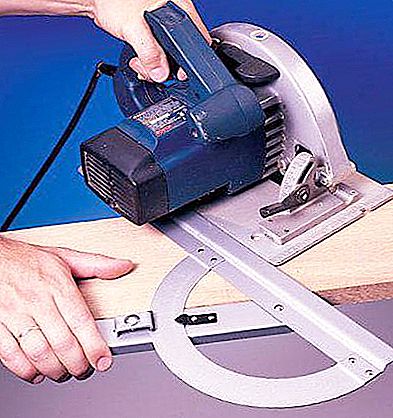

The presented type of power tool is designed for direct longitudinal cutting of various materials from wood, as well as plywood, chipboard, fiberboard, MDF panels. It can also carry out cross cutting.

Outside the competence of the equipment presented, there are usually dense building materials (brick, plaster, concrete). A hand-held circular saw with the possibility of stationary installation of Makita (some models, for example, 4101RH) comes with diamond blades and a water supply system. But this is rather an exception to the rule. The usual average instrument of domestic or foreign production can not boast of such qualities. But it can be easily used for cutting sandwich panels, plastic, laminate or even plexiglass. Quite often, in modern models, the possibility of cutting slate is provided.

Circular disk

The very first criteria for choosing a stationary circular saw are cutting discs. Their diameter, shape and material determine the type of work for which the equipment is suitable.

This element determines the depth of cut. Engine power directly depends on it. The larger the diameter of the blade, the more complex the principle of equipment systems. For large cutting elements, a more complex stabilization system is used.

This affects the weight and cost of the tool. For professional processing of materials, it is necessary to purchase circulars with a disk diameter of 165-240 mm. For home use, 140-150 mm products are quite suitable. 150-165 mm discs are considered universal. They are suitable for almost all types of work.

Engine power

The stability class of its operation, as well as the duration of continuous operation, depends on the power class of the equipment motor. This, accordingly, affects the speed of cutting materials.

For domestic purposes, a device with a capacity of 800 watts is suitable. Universal are considered models of 900-1200 watts. These, for example, can be attributed to a hand-held circular saw with the possibility of a stationary installation "Interskol" DP 165, which is quite popular today among craftsmen of different levels.

For professional activities, it is customary to purchase equipment with a capacity of more than 1200 watts.

Speed

The rotational speed of the disc is one of the main parameters that characterizes the circular saw hand with the possibility of stationary installation. Which model to choose will be easier to understand after a detailed examination of this characteristic.

Together with the shape of the disc and the size of its teeth, the rotational speed affects the cleanliness of the cut. The higher the speed, the greater the torque.

This parameter also affects the heating temperature of the material during processing. If the speed is too high, plastic panels and workpieces cannot be cut using such a technique. The edges will just melt.

If the model provides for speed adjustment, then this is a more versatile device. Otherwise, the torque is selected purely for the conditions of work.

Protection system

Many manufacturers provide various protection systems for the operator and equipment in the process. These are important options that a hand-held circular saw should have with the option of stationary installation. Doing it yourself will not only be easy, but also safe.

Saving on a protection system is highly discouraged. Circular - equipment that relates to power tools of high hazard class.

Protective elements include a device that maintains a constant speed. Soft start prevents overheating of the unit and its engine.

A very useful option provided in some models is to turn off the system at high loads.

The electrodynamic brake is able to instantly stop the rotation of the disk when the master releases the rotation button.

Consumer Reviews

Today, the market for power tools presents many copies of equipment from foreign and domestic manufacturers. Their cost is quite different.

Users noted that for domestic work, inexpensive domestic copies are quite suitable. A hand-held circular saw with the possibility of stationary installation "Baikal", as well as "Fiolent", "Interskol" proved their reliability, which earned popular recognition.

Professionals choose models of foreign brands Bosch, Makita, AEG, etc. This is due to the greater specialization of such equipment, which is perfectly suitable for industrial production.