Almost until the end of the 16th century in Kievan and then in Muscovite Rus, the main raw material base for iron production was marsh and lake ores lying close to the surface. They are referred to by the scientific term as “brown iron ore of organic origin” or “limonite”. The current names of some settlements, tracts and streams still reflect the interest of antiquity in this raw material: the village of Zheleznyaki, the Rudokop reservoir, the Rzhavets stream. An unpretentious marsh resource betrayed iron of very dubious quality, but it was it that saved the Russian state for a long time.

Swamp ore characteristics

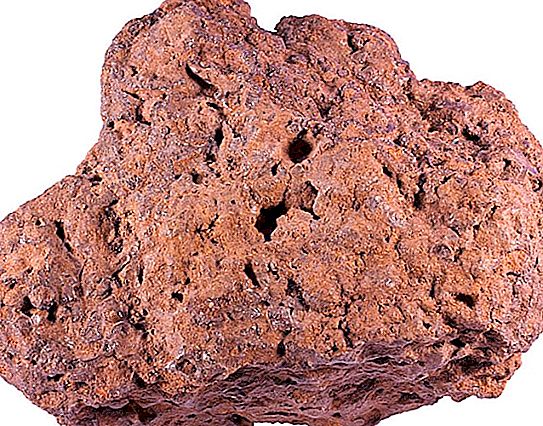

The ore in the swamps is a type of brown iron ore deposited in a swampy area on the rhizomes of aquatic plants. In appearance, it usually is a placer or thick, earthy pieces of red-red hues, the composition of which is mostly represented by iron oxide hydrate, and also includes water and various impurities. Not so often in the composition you can find oxide of nickel, chromium, titanium or phosphorus.

Swamp ores are poor in iron content (from 18% to 40%), but have one indisputable advantage: metal smelting from them occurs at a temperature of only 400 degrees Celsius, and 700-800 degrees can already produce iron of acceptable quality. Thus, production from such raw materials can easily be established in simple furnaces.

Swamp ore is widespread in Eastern Europe and everywhere accompanies temperate forests. The southern border of its distribution coincides with the southern border of the forest-steppe. In the steppe zones, iron ore of this type is almost absent.

According to the pages of history

Swamp ore for a long time prevailed over vein ore. In ancient Russia, for the manufacture of iron products, resorted to ore collected in the swamps. They removed it with a scoop, removing a thin layer of vegetation from above. Therefore, such ore is also known as "turf" or "meadow".

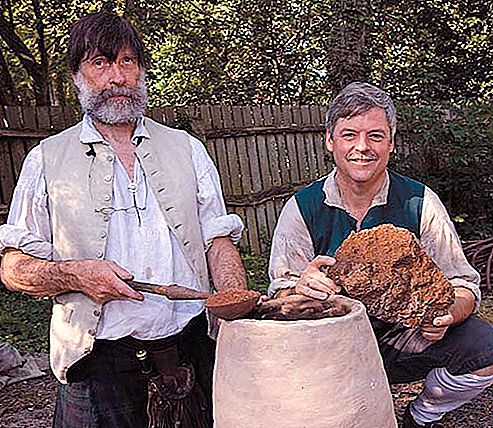

The extraction of iron from swamp ore was a purely rural craft. Peasants went fishing, as a rule, at the end of the summer season and early autumn. When searching for ore, a wooden stake with a pointed end was used, which pierced the top layer of sod, immersing 20-35 centimeters to a shallow depth. The search results of the miners were crowned with a certain sound produced by the stake, and then the recoverable rock was determined by the color and taste of the piece. It took up to two months to dry the ore from excess moisture, and in October it was already calcined at the stake, burning various impurities. The final smelting was carried out in the winter in blast furnaces. The secrets of how to get swamp ore were inherited and kept for generations.

It is interesting that in the Old Russian language the token “ore” was used in the meaning of both ore and blood, and the derivative “ore” was synonymous with “red” and “red”.

Ore formation

In 1836, the German geologist H. G. Ehrenberg first formulated the hypothesis that the growing bottom sediments of brown iron ore in the swamp are the result of the activity of iron bacteria. At the same time, despite the free development in the natural environment, this main organizer of swamp ore to this day is not amenable to dilution in laboratory conditions. Its cells are covered with a kind of cover made of iron hydroxide. Thus, in the reservoirs through the development and vital activity of iron bacteria, a gradual accumulation of iron occurs.

The scattered particles of the iron salt of the primary deposit pass into the groundwater and, with significant accumulation, settle in loose shallow sediments in the form of nests, kidneys or lenses. These ores are found in low and very humid places, as well as in river and lake valleys.

Another factor influencing the formation of swamp ore is a series of redox processes in the overall development of the swamp system.

Place of Birth

The largest marsh ore deposits in Russia are located in the Urals, where the total reserve of all deposits is about 16.5 million tons. Brown iron ore of organic origin contains iron from 47% to 52%, the presence of alumina and silica is in moderate limits. Such ore is advantageously used for smelting.

In the Karelian Republic, in the Novgorod, Tver and Leningrad regions there are goethite deposits (iron oxide hydrate), which is mainly concentrated in swamps and lakes. And although it contains many unnecessary impurities, the ease of extraction and processing made it economically viable. The volumes of lake ore are so significant that in the iron mills of the Olonets district in 1891, the extraction of these ores reached 535, 000 pounds, and 189, 500 pounds of pig iron were smelted.

Tula and Lipetsk regions are also rich in birch-iron ore of bog genesis. The iron in the composition ranges from 30-40%, there is a high content of manganese.

Production Features

Swamp ore today is hardly regarded as a mineral and does not cause much interest for the development of local industry. And if for metallurgy the insignificant capacity of ore-bearing strata is of no value, then they are just right for home amateur hobby.

In nature, such ore is found of all kinds and qualities, from voluminous bobbins and small crumbs to a sapropel-like structure. Their deposits are located at the bottom of the swamps, in the lowlands and on the slopes of the hills adjacent to them. Experienced fishermen determine their location by the characteristic rusty water and dark silt on the surface of the swamps, as well as by a number of other signs. Having removed the upper layer of soil, often knee-deep in water, and sometimes even to the waist, they remove the “iron earth” of red-red hues. It is worth noting that the ore from high places and under the thickets of birch forests is considered the best, since the iron from it will be softer, but harder iron is obtained from the ore located under the spruce forests.

The process from time immemorial has not changed much and involves a primitive sorting of raw materials, cleaning of plant residues and grinding. Then the ore is stacked on dry places, on the ground or on special wooden flooring and left for a while to dry. At the final stage, it is burned to remove the remaining organics and sent for smelting to the furnaces.