Railways are the main industrial arteries of any developed country. It is difficult to imagine modern life without them. Rail transport impresses with its low cost and the ability to transport massive loads. Therefore, they have found such widespread use in the industrial sector, allowing large enterprises to save huge sums.

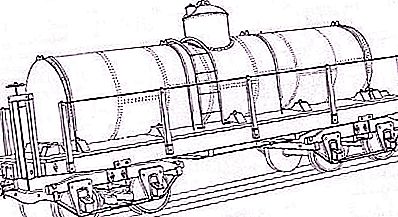

The railway tank is one of the varieties of rolling stock. It is used mainly for the transportation of petroleum products, acids, alkalis and other aggressive substances, as well as flour, cement, liquefied gas, milk.

Types

There are different types of railway tanks:

- General purpose tank. In such cases, petroleum products are most often transported.

- Special tanks intended for the transportation of strictly defined goods.

The railway tank can be used both for ordinary, not very picky liquids, and for those that are under pressure. A container for transporting liquefied gases and other goods requiring high pressure is called a vessel. When you need to observe certain storage temperatures, you have to use cryogenic types. If necessary, the inner walls of the tank can be protected with a special coating that prevents corrosion.

General purpose tank

Most of the tanks plowing the railways are of general types. They are much cheaper than their specialized “colleagues” and are ideal for transporting liquid petroleum products that do not require heating during discharge or filling. Typically, general purpose tanks have the simplest design and are not equipped with sophisticated measuring equipment or other technological innovations.

Special tank

Special types are much less common than ordinary ones, and they are mainly needed by organizations that use transported liquids in production. Such a railroad tank car can be quite complicated, it can be used to transport liquefied gases under pressure, to transport acids and alkalis, and various toxic and aggressive substances.

Special purpose tanks are often equipped with sophisticated technical devices, so a separate instruction manual is written for each. It considers the correct discharge of railway tanks, and also notes the design features, the rules of maintenance and operation of this product.

Constructions

Modern railway tanks come in a wide variety of designs, but two main types can be distinguished - with and without a frame. Differences in structure do not affect the volume of the railway tank. The design with the frame differs only in that the load passing through the wagons in it is transmitted along the frame, excluding the tank itself.

The frameless version, on the contrary, allows traction and shock loads to be transmitted through a tank that plays the role of a frame. If the volume of the railway tank is too large, then it is reliably strengthened with steel rings on the outside or inside.

The design of railway tanks also varies in number of axles. You can find four-, six-, eight-axis variants. The higher their number, the greater the volume of the product. Also on the case must be stairs and hatches for draining the liquid.

Loading

Before loading the liquid, the railway tank must undergo appropriate maintenance and preparation for loading. For specialized types, loading procedures can vary widely, but there are a few general rules that apply to most tanks.

First of all, it is necessary to wait for the rolling stock to stop completely, then clean the stairs and hatches from dirt or snow, if any. Next, you need to unscrew the pressure relief valve to make sure that there is no pressure in the tank. Then you should open and securely lock the manhole covers. After that, inspect the inside of the tank and remove any foreign bodies from there. Then, all structural elements are checked, all parts and assemblies are checked. Particular attention is paid to the presence of butterfly valves and bolts that attach the aerial plates to the flanges of the cones of the boiler hoppers.

When all necessary procedures are completed, loading of the tank will begin. After it is fully completed, manhole covers should be tightly closed and sealed. The last steps - cleaning the outside of the tank from the parts of the cargo that have fallen on it.